Normally, with practice, I can get the hang of any tool I’ve tried. Not so with small, handheld belt sanders. I’m forever gouging wood. Even when I go slow and think I’m level, I’m not. What am I doing wrong? – Kimberly Sutherland

Tim Inman: It’s all in the wrist. You’re on the right track, though — getting the “hang” of it is the key. Going slow is probably your enemy, too. Learn to move with a smooth fluid motion. It’s a lot like the “dance of the wood smoothness fairy.” Get into the flow of it. Another thing that helps beginners — either new to the trade or new to the tool — is to use a finer grit than you think you want or need. Less gnarly sandpaper means less gnarly faults. Relax, go loose, play music, don’t worry. Practice on thin veneered scrap plywood. Learn how to take off the veneer evenly all over the surface at one time. Then you’ll know the tool and be ready to take on the “real” project.

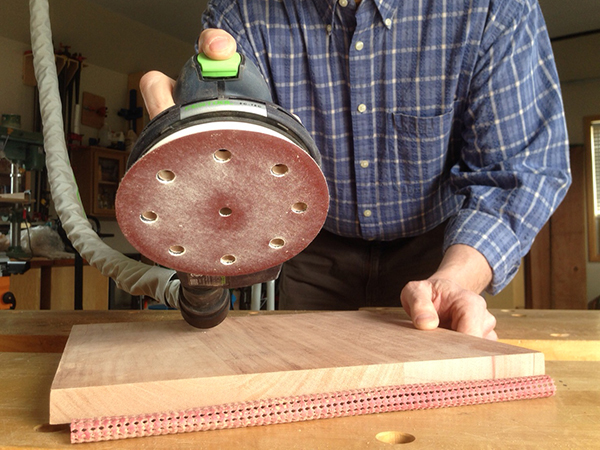

Chris Marshall: I have a couple of belt sanders, but I don’t use them much. When I do, it’s only for heavy stock removal at the first stages of a project. Instead, I use a jointer, planer, a few hand planes and a random-orbit sander as my main surfacing tools. A coarse-grit disc on a random-orbit (RO) sander does pretty quick work. I’m sure you’d find an RO easier to control than a belt sander, because it won’t try to pull you along as a belt sander does. I feel like I’m fighting against a belt sander’s motion in order to control it, and wrestling the tool doesn’t help improve the results. Between the two types of sanders, a RO is almost always my preference.