I have been trying to find a jig to help me cut small-scale wooden parts. The scale is one half inch to the foot, to be used for buildings in garden railroads. Would you have any ideas? – Jim Evans

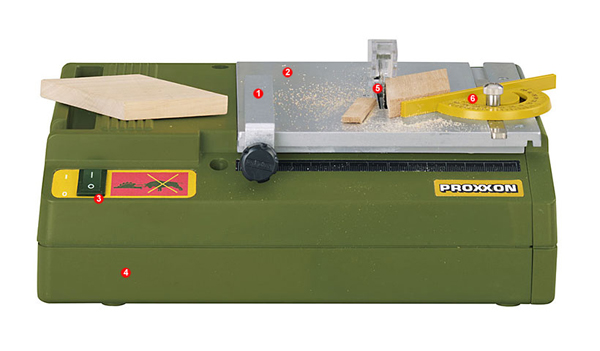

Chris Marshall: When I was a kid, I had dreams of building a full diorama of buildings and bridges for my HO-scale model railroad set (I’m sure every ‘70s kid with a train set had the same dream…), so your question brings back some nice memories. Somewhere around that time, I learned about a company called PROXXON that makes woodworking machines for miniature hobbies of this sort. If you’ve never heard of them, here’s a link. Have a look at their little KS 115 Bench Circular Saw with a 2-9/16-in.-dia. saw blade — it has 80 teeth! Maybe some of our eZine readers have experience with PROXXON tools and will share some feedback about them.

But, all dreaming aside, I’m not sure cutting miniature parts requires miniature tools — even though the thought of trying out a tiny table saw seems like fun. Instead, I think the more reasonable approach and set of concerns for a woodworker with “full-size” tools issue is how to feed tiny pieces of wood next to a large blade without cutting your fingernails in the process. Or leaving saw marks in your miniature “lumber” parts. Hence, the question you raise for us. What I’d probably do is make a simple crosscut sled with an aluminum T-track that fits in your saw’s miter slot or slots — there are plenty of crosscut sled plans online. The sled should have as little side-to-side play as possible when you slide it across the saw table to ensure that the cuts will be clean, right off the blade.

Rockler has a new Small Parts Sled for making crosscuts on the table saw (see below), and you can read more about that by clicking over to “What’s In Store” in this issue. It’s intended for crosscuts only.

As you’ve probably experienced, a circular saw blade will sometimes catch tiny offcuts and shoot them here or there, but a band saw blade won’t do that. For this reason, I think I’d fashion a sled to work on my band saw instead of the table saw. My sled would fit in just one miter slot on the band saw table with a base positioned on only one side of the blade.

Regardless of the style of sled you make or whether it works on a table saw or band saw, keep your fingers clear by starting with oversized workpieces whenever possible and holding stock with push blocks, scraps of wood or hold-down clamps. Whatever fixtures or fences you create to use with your sled — and I’m sure there will be several required for using the same sled to both rip and crosscut parts — I think a single sled could take care of just about all of your miniature-parts cutting needs.

Do other eZine readers make miniature parts for train sets, dollhouses and the like? Please offer Jim your advice for what type of cutting jig and methodology works best for you.