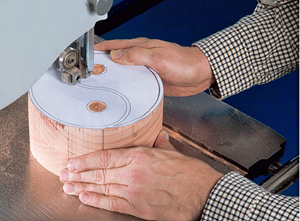

I have a 17-in. Grizzly, using a Highland Working 4 tpi skip-tooth 3/16 in. blade. I am making band saw boxes averaging 4 inches thick. Problem is: the blades are leaving horrible, rippling-like gouges. Takes forever to sand, even using a spindle sander. What is causing this and how do I fix it please? All this sanding is making drawers a little loose. – Andy Roff

Tim Inman: A wider, finer blade would probably be my choice. That thin, coarse blade shouldn’t be expected to give ultra-smooth cuts in thick tough work. It might be a little lopse, too. That would contribute to wobble and twisting and tearing.

Chris Marshall: Since you are making band saw boxes, I can see where bad cuts are really frustrating. And any significant amount of sanding impacts both the look of the drawers and their tolerance in the box. I agree with Tim. Try a higher tooth count blade and see if cutting smoothness doesn’t improve — even if it means the cuts take longer to make. If the cuts you are currently getting are flat from top to bottom, then the blade tension is OK, but try scooting those side guides in until they almost touch the blade.