About a year ago, Harvey Industries purchased Bridge City Tool Works (BCTW) from its founder, John Economaki. For some 35 years, Economaki had been designing and producing premium quality measuring and marking tools and hand planes from his company’s Portland, Oregon, headquarters. At the time, Harvey owner Jack Xu and Economaki had been both friends and business partners for more than five years. Harvey had been producing 25 BCTW products in its Nanjing, China, factory for distribution outside the U.S. (You can read more about this acquisition by clicking here or a separate interview about Harvey Industries by clicking here.)

Since then, numerous changes have taken place for Bridge City. Key among them has been the appointment of Mark Strahler as Bridge City’s new president. Strahler has a long tenure in the woodworking machinery business. He was once the vice president of marketing and sales for Delta Machinery before it merged with Porter-Cable.

“I was very proud to be part of the team that led Delta Machinery to the leadership position in woodworking machinery. After my time with Delta, I started Orion, a new company that manufactured OEM products primarily for Sears Craftsman. Together with that team, we successfully built numerous quality tools including table saws, jointers, drill presses, dust collectors and grinders for Sears.”

Strahler was also instrumental in starting up Steel City Tool Works in 2005 with five other former Delta employees. When Steel City intended to add table saws and shapers to its product offerings, the search for a supplier led them to Harvey Industries and Jack Xu, who fulfilled the need.

“We immediately recognized that Jack and Harvey Machinery were unlike many of the other OEM factories. He was driven to innovate — not just build another saw, but to build the very best,” Strahler says. “(That) started Jack on the path as an OEM manufacturer for some of the major woodworking companies in the industry.”

When Steel City shuttered its operations, Strahler rejoined Delta Equipment Company in 2011, where Harvey Industries was also serving as an OEM source for some of Delta’s tools. Strahler eventually started his own company, MGS Options, LLC, where he provided import/export consulting services for Harvey Industries and other companies. In that capacity, Strahler helped Xu introduce Harvey-branded machinery, such as the T40 Turbo Lathe and GYRO Air Dust Processors, to the North American market.

Aside from Strahler stepping into his leadership position, another big change for BCTW happened last July, when the company moved from Portland to Montclair, California. Harvey Industries headquarters its North American operations there. Montclair now serves as Bridge City’s administrative and customer service centers, warehouse and product showroom. It’s been a smooth transition that Strahler credits in part to a good BCTW team.

“With regular visits from me, (the team in California) has worked extremely hard to establish the business processes to support the BCTW line and make it work with the existing Harvey Industries business already established in California,” Strahler says.

Strahler adds that his staff has also done a “tremendous job” of continuing to uphold the company’s excellent reputation for customer responsiveness during the move and the subsequent settling process.

At last year’s acquisition, Economaki planned to stay on with the company for a couple of years. These days, he’s working on new designs and redesigns for Bridge City products. In fact, Strahler says John is “feverishly” developing a number of new items for the catalog that the company hopes to launch in June or July. Economaki has gone back to some older tool offerings and is recreating them in order to improve their design and functionality.

“Being free of the day-to-day interruptions of running a business, he is accomplishing more than he had hoped,” Strahler says. “He has enough projects designed for BCTW for the next three years and has plans to continue additional designs thereafter.”

But eventually, John does plan to fully retire. So, Strahler says the company is currently seeking a few talented woodworking tool designers to mentor under John’s tutelage, learn his design philosophies and carry his ideas forward.

Still, those will be big shoes to fill. “There is only one John Economaki, and there will never be anyone who could fully replace him,” Strahler says. “(John) has an in-depth knowledge of how tools should work, feel and look, and he has the ability to communicate all of this to his customers.”

As some of those products change, so do the supply chains for their components. Historically, Bridge City sourced the parts for its North American products from small suppliers, primarily in the Pacific Northwest. That is no longer the case under the new Harvey ownership. Going forward, Strahler says the company has no plans to build any products in the U.S., because doing so would result in a duplication of people and equipment that already exists in Harvey’s Chinese factory. It’s a perplexing reality that faces woodworkers who would prefer to purchase tools made in the United States rather than the Pacific Rim. The “Made in China” stigma is one Strahler says the company deals with every day, and some of the criticism of Chinese-made tools and machinery is justified.

Strahler is quick to clarify that while some “cheap” and low quality woodworking tools continue to be made in China, that’s not the whole story. There’s also a “high quality” end of the product spectrum. It all depends on sourcing.

“Apple’s products that perform well and function beautifully are made in China. Does anyone ever question those? Quality is available from Chinese suppliers if you are willing and committed to demand it and if you are working with the right companies. Harvey Industries is one of those companies,” Strahler says.

He credits Xu’s commitment to high standards for sourcing, innovation and a “tireless demand for perfection” as the attributes that will ensure that Harvey Industries will continue to build premium quality woodworking machines as well as Bridge City hand tools.

Quality assurance and better inventory control are two reasons that BCTW is also “taking it slowly” in the U.S., Strahler points out. “We want to be sure we have a consistent flow of perfect products before we aggressively start to advertise and reach out to a wider customer base.”

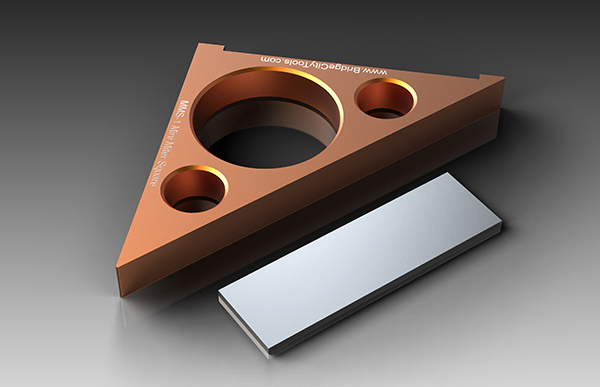

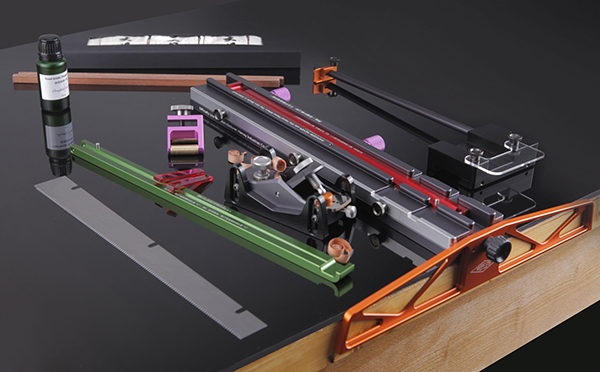

Part of that outreach will also involve creating new videos that will introduce the functionality, beauty and versatility of Bridge City’s product line to new segments of the market that might not be familiar with them yet.

For those who are already established BCTW customers, Strahler says the company soon will be reintroducing the Universal Guide, scratch awls and an improved Center Scribe. Economaki will also be blogging soon about a couple of new hand planes that will launch in the next few months.

Overall, Strahler is pleased with Bridge City’s prospects, and he sees the opportunity to help grow that legacy as an exciting and big personal challenge.

“At this stage in my life, I’m no longer interested in working just to work. It has to be more … otherwise, why do it? It’s the same principle with Bridge City Tool Works. Why just buy another cheap T-square? Why not buy something that’s fun to use, is accurate and makes you smile when you pick it up? We are all working to make that happen for woodworkers every day.”

Learn more about Bridge City Tool Works by clicking here.