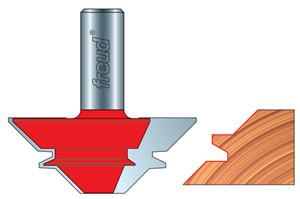

I was given a 45 degree lock miter bit for my shaper and I was wondering if there was any information on how to set the bit height for making corners that will fit. – Dave Moodie

Tim Inman: I think trial and error is the best bet for you here. Always make a test piece whenever you do a machine setup. When you do, you both gain immediate experience using your machine and the cutter, and you discover the little idiosyncrasies of your setup.

Chris Marshall: Lock miter bits and cutters are tricky to set up and use. I read an article several years ago that suggested some fairly sophisticated mathematics for setting up the bit in a router table, but I’ve had success in the past using a plastic setup block that often can be ordered as an accessory for the bit. But, you are using a shaper cutter and not the router bit, so an accessory setup block probably isn’t going to be available to you. Speaking again about the router bit approach, even with the setup block, I’ve still found that I need to shift the bit height up or down or adjust the fence in or out a smidgen more to establish a perfectly fitting joint — not too loose, not too tight, interlock meeting evenly and outside corners coming together in a crisp edge. If you’re like me, you’re going to need to make some test cuts … maybe even lots of test cuts … and keep your patience in check. It’s a cool-looking and solid joint once you get things set correctly, but it’s definitely not the simplest bit in the collection to master. No question about that. Once you get a joint that fits just right, cut another piece from hardwood to save as your own shop-made setup block for next time. Good luck!