Despite the name, sandpaper isn’t made with sand. Natural minerals like flint and garnet were once mainstays but have largely been replaced with synthetic materials. Neither garnet nor flint is particularly friable, meaning that the grains don’t fracture to expose fresh sharp edges as well as others. They’re okay for hand-sanding but wear quickly with machine use.

The three most useful abrasives for woodworkers are aluminum oxide, silicon carbide and ceramic.

Aluminum oxide is by far the most common material. It’s moderately priced, very friable and has a decentlifespan. You can’t go wrong making this type your go-to for day-to-day use. It’s also the most readily available due to its popularity.

Silicon carbide is a harder, sharper material that lasts longer than aluminum oxide. It’s often available in extremely high grits — I have some 2,000-grit in my shop — and it’s great for wet-sanding and rubbing out finishes. It’s also a bit more expensive.

Ceramic abrasive paper for woodworking is more recent. It’s very hard, and although somewhat less friable than the other two types, the grains remain sharp until depleted, making it incredibly tough and aggressive. It’s a bit pricey by comparison, but it easily lasts the longest of the three.

Sandpaper is either open- or closed-coat. Open-coat paper uses less grit, creating spaces between the grains that help prevent clogging or “loading.” It’s best for softwoods and other high-resin materials. Closed-coat is just the opposite, with the grains densely packed together. It’s best for harder, low-resin woods and for hand-sanding.

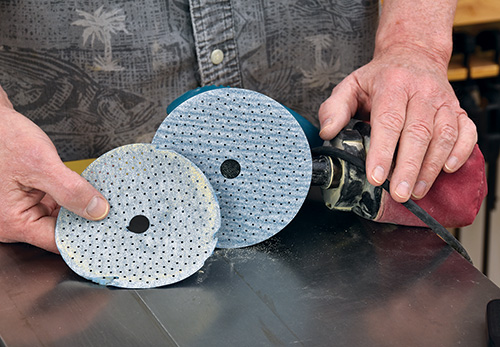

Speaking of longevity, it’s natural to want to use a disc or belt as long as possible. But overused sandpaper is an exercise in diminishing returns. Resin buildup, torn edges and dust holes and “bald” spots all lessen sandpaper’s effectiveness, leading to poor results that, maddeningly, take longer to achieve. Check your paper often, and discard paper sooner rather than later.

That said, if paper is still fairly new but clogging, extend its life by simply cleaning it. A stiff brush — an old toothbrush or even a soft wire brush — can remove a lot of buildup, while a gum cleaning block helps with more serious clogging.