I’m building a stand for a saltwater aquarium and would like to know what you think would be the best finish to put on it? There will be a cap on top of the aquarium that would be exposed to the salty air coming off the water. The project is being made out of red oak. Any help would be appreciated. – John Langdon

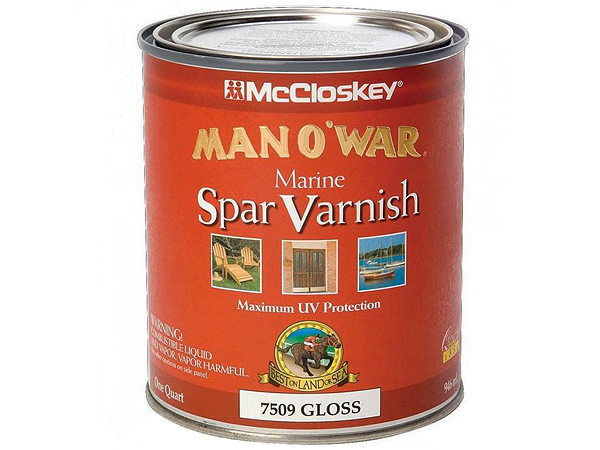

Tim Inman: Use a marine spar varnish. A marine spar polyurethane should be good and easy to get. But there is no finish that will long endure constant saltwater exposure. Be prepared for a continuous maintenance plan. Also, red oak will be very prone to turning blue or black if it gets wet, especially with high mineral content water.

Chris Marshall: Reptiles were a hobby of mine for many years. While their enclosures weren’t a challenge to finish in terms of saltwater exposure, coming up with an easy-to-clean, durable interior surface that wouldn’t peel, crack, blister, etc., from heat, moisture and other organic stains was a very real priority for me. So, I’ll offer a different suggestion from Tim. For the surfaces that will have potential water contact from spray, dense vapor, splashes and leaks, consider covering them with plastic countertop laminate instead of a wood finish. I found laminate to be incredibly durable and easy to wipe clean. It’s impervious to water, and I highly doubt it will be affected by salt. You can buy plastic laminate online or at some home centers — my local Lowe’s carries it in 4×8 sheets in several colors for around $75. Online sources sell it in dozens of colors and shades; I’ve bought it that way before with good success.

Plastic laminate is DIY friendly, and you can use ordinary woodworking tools and machines to cut, rout and drill through it. The challenge, however, is bonding it securely to the surface underneath. Typically, the adhesive of choice is contact cement, and that’s what I’ve used mostly. Generally it works pretty well, but occasionally the cement will loosen its grip in some areas (particularly along edges and at corners). We might have some countertop fabricators among our Weekly readers who can suggest even better adhesives from their experiences — and folks, please do!

I’d finish the outer wood surfaces of your stand with spar varnish, as Tim suggests. Then, I’d use laminate inside the project for the surface the fish tank sits on and as a liner for the cap on top, plus any other interior areas that will be subjected to water and water vapor.

One other point of clarification: melamine-coated particleboard is no substitute for plastic laminate. It might look like a more economical, suitable alternative, but the melamine coating is so thin that water will penetrate it sooner or later. Once that happens, it’s all downhill from there, because the particleboard core will blister, swell and crumble when it gets soggy. Instead, spend more on the front end and get real plastic laminate for your stand — it will outlast melamine board exponentially.

Good luck with your project!