Typical family-run businesses are founded by a parent and continue with offspring. But, a refreshing aspect of the father/son team at Lake Erie Toolworks is that the order of seniority is the other way around.

Nick Dombrowski started the company about ten years ago, after working for a stint in the mill, keyboard and console departments of Organ Supply Company in Erie, Pennsylvania. “It’s a company that supplies organ builders and repair companies with anything and everything to build and repair pipe organs,” he says.

He worked there part-time and during breaks from college at Gannon University, where he was pursuing a degree in theology. He credits his woodworking and machine shop classes in high school, as well as his work at Organ Supply, for the majority of his formal woodworking education. That, and a couple of week-long classes under the tutelage of Ernie Conover, learning hand tool joinery and spindle turning.

Nick’s father Jeff, who is partial owner of Lake Erie Toolworks, joined his son’s company early on to help guide its sales, marketing and website activities, while Nick focuses on the design, development and engineering side of the business.

“After pursuing a bachelor’s degree in pre-med, getting married, earning an MBA and raising three children, I somehow still managed to keep plugging away with the occasional woodworking project while I worked my normal day job,” Jeff says.

Those woodworking interests were fostered by Jeff’s father — a machinist and “mechanical wizard handyman type” who showed him the ropes growing up. But Jeff also benefited from four years of carpentry and cabinetmaking classes while attending a technical high school.

These days, Jeff works full-time for a large global technology company, where he’s been involved with sales, marketing, engineering and support. His portfolio of experiences are helping to guide Lake Erie’s business efforts when Jeff helps out on evenings and weekends.

Also in the front office from day to day, Nick’s wife, Rachel, manages its bookkeeping and office duties. “We’re a small family business with big plans for the future,” Jeff says.

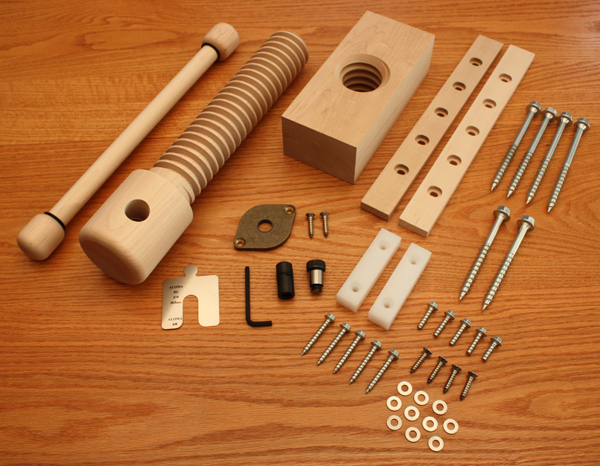

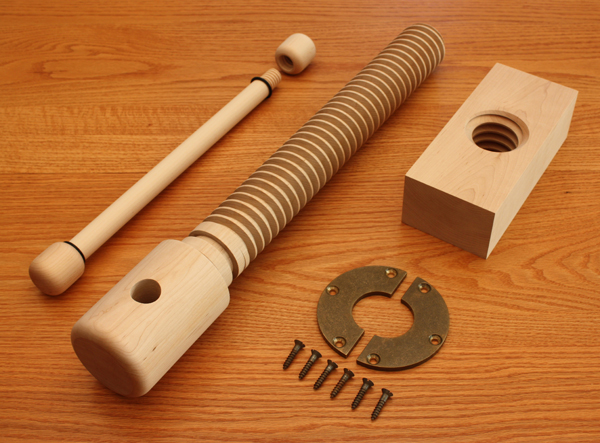

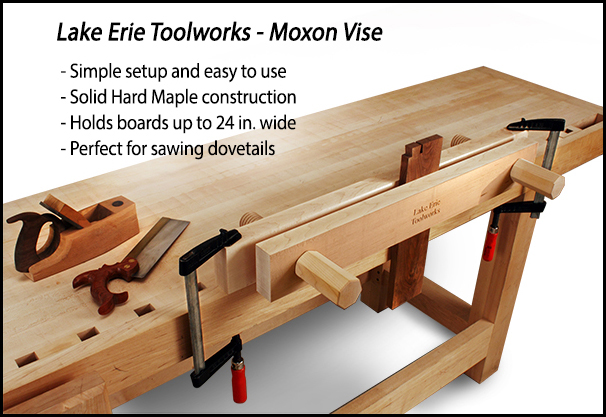

Aside from its somewhat unorthodox chain of command, another interesting point of note about Lake Erie Toolworks is its unique line of wooden clamping products. One might say, it’s a mix of “old-school tradition” made by modern manufacturing methods for today’s woodworker. The company builds wooden vise screws, wagon and shoulder vise kits and Moxon Vises — with their major components made of hard maple rather than steel.

Nick reflects that, initially, he wanted Lake Erie Toolworks to manufacture workbenches. But, space and equipment limitations changed that action plan for the fledgling company. Instead, after surveying the market and determining that there weren’t enough “quality” vises on the market, Nick decided to focus on workbench hardware. The decision was both pragmatic and romantic, Nick admits, reflecting back on his shop time at Organ Supply.

“Each woodworker (there) had an old Christiansen workbench with large wooden vise screws,” Nick says. “I fell in love with the look and feel of them.”

So, Nick spent about six months experimenting with CNC equipment, as well as building some custom machinery that would enable him to make wood vise and nut components. It also helped that his post-theology graduate work had shifted from religious studies into mechanical engineering, where he subsequently has earned a master’s degree.

Still, one might wonder, why make workbench vises out of wood? It would seem that metal would make a longer-lasting vise. But, the company offers a “white paper” on its website advocating why hard maple is an excellent mechanical choice for vise applications. For one, it offers superior shear strength along the grain over other woods, and shear strength has the largest impact on whether a wooden vise’s threads can withstand clamping forces. Hard maple’s fine pore structure, density and hardness contribute to stronger wooden threads that are less prone to chipping than more open-pored woods like oak or ash. It also provides larger total surface area for better wear resistance.

Nick has modified the thread pitch to make his maple vises more efficient to operate than metal vises, too. “Our vises move exactly 1 in. for every two turns of the handle,” he says. “Most steel vises, with some exceptions, take four to six turns to move 1 in., so you will be turning the handle two to three times as much for the same vise travel.”

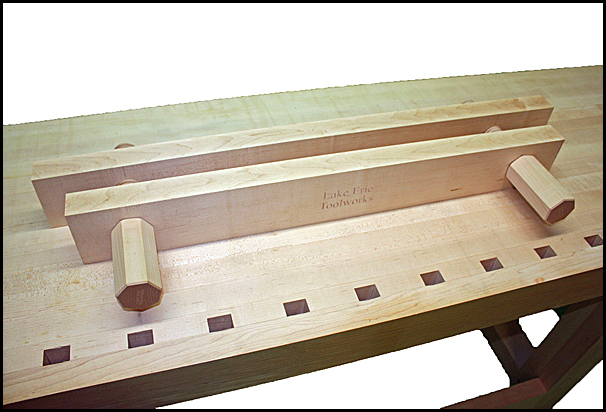

Lake Erie’s Wagon and Shoulder Vise Kits can be retrofitted to existing workbenches or integrated into a bench that you build from scratch. The company also makes an all-maple Moxon Vise, which offers long clamping surfaces and twin-screw strength in a self-contained product that can be clamped to any benchtop or other horizontal work surface. Named after the 17th-century woodworker, Joseph Moxon, who invented the concept, the Moxon Vise is ideal for holding long or wide panels for sawing joinery. And, it offers a broad, sturdy clamping solution for woodworkers who don’t have a cabinetmaker’s bench with integrated vises.

“We manufacture our Moxon Vise because the world needs a high quality all-wood vise that has the same benefits as our other wooden vises: fast, smooth action and tactile feedback while tightening,” Nick says.

Last year, however, Lake Erie broke from its “norm” and created a new clamping accessory that’s made of aluminum instead of wood. “ClampGAUGE” is a precision machined “spring” that’s used in conjunction with bar or pipe clamps. It’s designed to bottom out when the correct amount of clamping pressure is applied to a panel during glue-up.

Nick says that, while working on a design for a clamp attachment that would distribute clamping force over a broader area, the flexible characteristic seemed like a flaw and not a benefit. But, working through the engineering further, Nick realized that ClampGAUGE’s flexibility actually makes it easy for anyone to see the point at which adequate clamping pressure is reached: when the bars flatten out and touch the workpiece, no more pressure need be applied.

“Glue manufacturers have recommended clamping pressures for panel glue-ups that ensure the strongest and longest-lasting glue joints. To date, only woodworking manufacturers could afford to invest in industrial clamping machines that ensure that proper board glue-up pressures are achieved,” Nick says. “Now, with the ClampGAUGE system, all woodworkers can benefit from stronger and longer-lasting panel and tabletop glue-ups.”

The Dombrowskis report that their most popular products are the premium Wood Vise Screw Kit and the Moxon Vise. They attribute speed and smooth action to the vise’s popularity, while the Moxon’s “use it anywhere” convenience makes it a hit. “(The Moxon) allows anyone to cut joinery, even if they don’t have a workbench; they can attach it to a kitchen table and get to work sawing dovetails,” Nick says.

Looking ahead, Lake Erie will soon release a smaller “Light” version of the Moxon Vise, and it can be pre-ordered now. Several variations of the new ClampGAUGE are also in the works for clamping up thicker panels and for use with lighter-duty clamps.

Additionally, the company soon will realize Nick’s original dream of producing custom workbenches, which the Dombrowskis reveal are in Lake Erie’s “near future” plans. But in the meantime, both son and father are enjoying seeing the company continue to mature and grow as Lake Erie Toolworks approaches its decade milestone.

“I actually get to make a living doing what I love, which is designing and building top quality tools for woodworkers,” Nick says.

“And I get to spend quality time with my son as well as join in on running this business as a partial owner,” Jeff adds. “We started with high quality clamping products, but it will continue to grow and expand into other woodworking tools in the years to come. I am a truly fortunate man.”

Learn more about Lake Erie Toolworks and its products by clicking here.