Cordless tools have been around a long time but have had limitations, like batteries that didn’t last long enough or weren’t powerful enough to allow cordless tools to take the place of their corded cousins. But battery technology has come a long way, with battery formulations based on lithium-ion (Li-ion) the current industry champ.

Combined with general improvements in the tools themselves (such as efficient brushless motors), batteries have evolved to a new level of excellence. Tools run longer. Battery shelf life is extended. Amp/hour ratings are going up without increasing battery weight and size.

Small touches and features are continually being added to newer batteries, making them more useful than ever. Most Li-ion batteries come with “fuel gauges” now, for example. Since Li-ion batteries are designed to operate at full power to a specific cutoff point, there’s none of the winding down that served as a warning with old NiCad tools. A visual gauge that shows how much charge is left saves a lot of time and hassle.

Other useful additions include Bluetooth connectivity with a host of functions, from monitoring to theft control. Products like cordless work lights and heated work gear — once considered impractical — are now available, taking advantage of longer battery runtimes. Thanks to built-in cooling techniques, batteries can be charged faster, too.

One user-favorite feature, the built-in USB charging port popping up on batteries, doesn’t have anything to do

with woodworking at all. The woodworking consumer, however, has been responsible for driving tool companies to make some specific improvements.

“For manufacturers, the [driving force] is providing power and runtime while managing heat,” says Theron Sherrod, brand manager for Bosch cordless tools.

“Users want more power and more runtime in a package that’s light and easy to maneuver. They also want batteries that last a long time, even under constant use,” Sherrod adds.

That’s a lot of demands, but by and large the industry has delivered.

Battery Basics

Although Li-ion batteries have been around in laptops and cell phones for a long time (that’s what they were developed for), they only made their way into our tools a bit more than a decade ago. Before that, nickel-based battery chemistry was the standard. Today, however, new tools using Ni-Cad and NiMH — at least those intended for serious work — are becoming a rare species.

“Not only does Lithium-ion beat out nickel-based platforms for energy density — work capacity to weight ratio — but also shelf life,” says Festool’s Rick Bush. “Ni-Cad has fallen out of favor not only for performance, but also environmental concerns, especially in Europe.”

Although older higher-end Ni-Cad tools are still supported by a few manufacturers in the way of replacement batteries (or adapters that enable older Ni-Cad tools to use new Li-ion batteries), don’t expect to see many new tools sporting nickel-based batteries.

It’s easy to get lost in the chemical properties and capabilities of the newer batteries, but sometimes just the names can be confusing. Logic says a 12-volt tool has higher voltage than a 10.8-volt tool; likewise for 20 and 18 volts. The truth is, they’re all the same. The higher figure is the optimal or maximum charge, while the lower figure represents the nominal voltage. The only difference is the description the manufacturer chooses to use.

“Nominal and optimal voltages are different,” explains Wayne Hart of Makita. “Eighteen volts is the nominal voltage that reflects voltage under actual use; 20 volts is the optimal voltage, fully charged, but prior to use. So 18-volt and 20-volt batteries are the same. The only difference is the voltage rating used by the manufacturer. In the 10.8-volt/12-volt category, most manufacturers have chosen to go with the optimal voltage.”

Cool Characters

Public Enemy #1 for cordless tool batteries is heat. This has always been the case, but with today’s more powerful Lithium-ion batteries, paying attention to how hot a battery gets is even more important. Companies have addressed the issue a number of ways, both physically and electronically.

One of the easiest ways is to allow some breathing room inside the battery. Instead of just packing the individual cells into a battery pack, today’s batteries incorporate some air spaces between cells that help curb overheating.

Electronics internal to batteries and chargers monitor heat. (With Bluetooth-connected batteries, some tool apps can tell you, on a phone or tablet, what that actual temperature is.) Batteries get hot when discharging in-use, sometimes resulting in tool shutdown. The same is true when charging. Even early Li-ion battery chargers checked battery temperature before starting the charging cycle, allowing the battery to cool before charging kicked in.

Now, more chargers are appearing with active cooling functions that not only protect the battery from excessive heat, but also speed up the charging process, a real boon for the typically long charge times of high-amp batteries. Festool’s AIRSTREAM batteries and chargers are designed to actively cool the battery with a dedicated channel.

“The battery channel provides a directed flow of air through the cells while isolating the cells from dust, debris and moisture during the charging process,” says Festool’s Rick Bush. “The charger has a fan-boosted airflow that draws cool air through the battery and then into the charger instead of from the charger to the battery.” According to Bush, this cuts down charging times by more than 60%.

Makita battery chargers, meanwhile, have a smart-charging system where the battery and charger communicate during the charging process to actively control current, voltage and temperature. Their charger is also fan-based.

“A fan inside the charger circulates air through the battery to cool the battery during charging,” says Makita’s Wayne Hart. “This smart-charging system produces the industry’s fastest battery charge times. For example, a Makita 18V LXT Lithium-Ion 5.0Ah battery will reach a full charge in only 45 minutes, while other 5.0Ah batteries in the category require over an hour to charge — that’s longer than the average lunch break!”

Users should always be aware of the conditions in which they use and store cordless batteries. You can’t lay a tool out in the sun all day or grab a battery from out of a hot car trunk and expect optimal performance — or a battery that lasts very long.

Building Beefier Batteries

Li-ion batteries of today have come a long way from Li-ion batteries of a decade ago. By tweaking chemistry and circuitry, manufacturers now offer the same voltage, but with increased cycle life, greater reliability and longer use without sacrifice of power.

“Users want more runtime, but they still need the power to drive a circular saw,” says RYOBI/RIDGID’s Jason Swanson. “With more products like miter saws being made, users need maximum power from their batteries. These new high-demand products require high-power batteries that have extended runtime.”

A key goal in increasing power was to do so without making batteries bigger and, of course, heavier. It’s a constant give-and-take battle the tool companies are winning.

“Advances in cell design — energy density — and manufacturing have allowed us to launch higher capacity batteries in the same footprint,” says DeWALT’s Ward Smith. “The 20V MAX* system launched in 2011 with the highest capacity battery at 3.0Ah. We now offer 4.0Ah and 5.0Ah in the same size and weight.”

The reverse is also true. If your needs are low-duty, a battery in the 2.0 amp/ hour range might meet your needs. If so, you’ll enjoy a battery that’s considerably lighter, is faster to charge and costs less to replace than its equivalent of 10 years ago.

Brushing Up

Some of the newest technology for batteries isn’t really for the batteries at all, but rather for the tools themselves — but still results in better battery performance. That’s why brushless motors are becoming more common.

Brushless motors don’t have carbon brushes in constant contact with the motor’s armature. Instead, with the brushes eliminated, the location of the internal magnets and the copper windings is reversed: the windings are on the outside of the motor, and the magnets on the inside, allowing for a more compact motor. Add monitoring electronics, and the result is a tool that uses battery power in a far more efficient way, runs cooler and extends the life of both battery and tool.

Makita is one of several companies now using the technology.

“Makita’s efficient BL Brushless motor is electronically controlled to optimize battery energy use for up to 50% longer runtime per battery charge than similar non-brushless tools,” says Wayne Hart. “Electronic controls efficiently use battery energy to match the changing demands of the application for increased power and speed when needed.”

Old-style brushed motors that typically run full-tilt all the time draw the same amount of power all the time. The electronics of a brushless motor can tell how the tool is being used, however, and adjust battery draw accordingly. Use a drill with a brushless motor in soft pine, for example, and it draws less current. Use the same drill on hard maple, and it pulls as much juice as it needs to complete the task.

All About the Amps

Those higher amp/hour ratings offer power options woodworkers can match to the work. If a tool is used continuously in a single session to, say, drive hundreds of drywall screws or break down a pile of stock into shorter lengths, a greater amp/hour rating has a higher capacity and keeps you working longer between recharges. The analogy product managers like to use is to liken a battery to a car’s gas tank: the bigger the tank, the farther you can go. Taking the car analogy a step further, if your driving is just a quick trip running to the grocery, you don’t need a lot of power or a big tank. On the other hand, if you’re pulling a trailer on a long trip up steep inclines, you need both. But there’s a trade-off. The higher the battery’s capacity, the bigger the battery, and the longer it takes to charge.

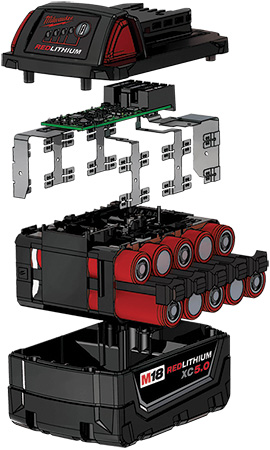

“So, obviously, lower-amp batteries will have the benefit of being more compact and lightweight. These batteries are ideal for drilling, fastening and overhead work,” says Andrew Lentz, senior product manager at Milwaukee Tool. “Just recently we enabled the biggest leap yet through the launch of our M18 REDLITHIUM HIGH DEMAND 9.0 battery that is built for high-demand applications.”

Lentz notes that the 9.0 amp/hour battery boasts up to five times more runtime and 35% more power than standard batteries, allowing it to power tools that rival corded versions. An example would be Milwaukee’s industry-first 18-volt full-size 10″ dual-bevel miter saw.

Making It Work

It’s not a single attribute like amp/hours that determines the overall power performance, but a combination of amp/hours and voltage called “watt/hours.”

“When talking about amp/hours, it is important to understand it in the context of voltage and watt/hours,” explains Makita’s Wayne Hart. “Watt/hours is calculated by multiplying nominal voltage and amp/hours. It is a key indicator of battery capacity and runtime.”

Using the car analogy, Hart described voltage as the size of the gas tank, amp/hours as the amount of gas in the tank, and watt/hours as the total distance you can drive in an hour (or how fast you can cover the distance). For example, the math for Makita’s 18V LXT 5.0Ah battery looks like this: 18 volts x 5.0 Ah = 90 watt/hours. That won’t give you 90 hours of use, of course — how the tool is used determines that — but the end result helps you gauge the performance of one battery over another.

Very Volty

Without doing any math at all, it’s pretty easy to compare a 12-volt tool to an 18-volt. Using a drill/driver as an example, a 12-volt version typically runs at lower speeds and may bog down under heavy load. If your intended use is light-duty — simple fastening chores or maybe furniture assembly — that’s fine, and you’ll enjoy using a lightweight tool. But for high-torque tasks like deck construction or powering hole saws all day, stepping up to an 18-volt drill/driver offers higher speed and stamina for heavier work.

Putting it simply, higher voltages offer lots of benefits for tools that spin really fast in heavy-duty use, or cut through dense material, or need to do both for an extended period of time. Almost any larger saw — circular, miter, reciprocating — used in thick and/or dense material certainly qualifies. Unless they’re intended for light-duty cutting, most of the offerings in this category come in 18-/20-volt versions.

Another benefit of higher voltages is that they have a lower current draw, which makes the power go further in-use. That means that an 18-/20-volt tool running at 2.0Ah will run longer than a 10.8-/12-volt tool running at the same amperage.

So, if 20 volts is good for heavy-duty work, wouldn’t even higher voltages be better? The answer is yes, and that’s why you’re starting to see them. Because of their intended uses outside the shop, a lot of woodworkers may not be aware they’re out there. Tools for yard work are good examples.

Very, Very Volty

Cordless hedge and string trimmers, lawnmowers, blowers and any other tool that must run continuously (and, in the case of trimmers and mowers, is used to cut continuously) lead the pack of high-voltage tools. In fact, yard tools of 36, 40 and 60 volts are becoming relatively common, with most woodworking tool manufacturers offering a line of yard maintenance tools as well. Briggs & Stratton, well known for their line of Snapper outdoor equipment, now offers an 82-volt line that includes an 18″ chainsaw.

It didn’t take long for the same manufacturers to realize that, even though the tasks are different, some woodworking tools operate with similar demands as yard tools. Several have added higher-voltage tools to their woodworking lines. How they achieve higher voltages varies.

Makita currently offers 36-volt versions of typical heavy-duty, power-hungry tools, including a vacuum, angle grinder, rotary hammer and circular, plunge-cut, reciprocating and miter saws. The surprise here is that the tools don’t use a special 36-volt battery that wouldn’t be compatible with anything else: they use the same batteries found on the company’s 18-volt line.

“Makita created a solution that lets users remain in the 18V platform and avoid having to invest in higher-voltage battery systems,” says Wayne Hart. “Makita 18V X2 (36V) LXT tools are powered by two 18-volt batteries for maximum performance and runtime. So users can expand their cordless system with 18V X2 saws, blowers, vacuums, recip saws, chainsaws and more, but without leaving the strongly preferred 18-volt battery platform.”

DeWALT has taken an entirely different direction with their 60V MAX* line by offering a battery with switchable voltage. Their FLEXVOLT batteries are really 20V MAX* batteries with a neat little trick up their electronic sleeves: Depending on the voltage requirements of the tool, the battery electronically switches from parallel wiring, which delivers 20 volts max at 6.0Ah, to 60 volts max at 3.0Ah (nominal 18 and 54 volts, respectively). So the same battery can power a 20V MAX* drill, and then be swapped over to their 60V MAX* circular saw, with the battery adjusting automatically to the tool. Drop two batteries into DeWALT’s new FLEXVOLT-based 12″ dual-bevel sliding miter saw, and the machine rocks out at 120 volts max (108 volts nominal).

Wait, what? Yeah, when it comes to comparing cordless tools to their corded counterparts, this machine makes comparisons easy. Running at 120 volts, the saw functionally is a corded saw, just no cord. In fact, if you have no need of the portable benefits of cordless with this machine, the miter saw includes an adapter so you can — coming full circle here — plug it into the shop wall.

Safety First

If you pay attention to the news, you’ve likely heard of Li-ion battery-powered “hoverboards” catching on fire. Scary stuff, but in most cases, battery fires can be attributed to batteries being used in a manner contrary to manufacturer recommendations. The same goes for battery-powered tools: the bottom line is that safe tool use is ultimately up to the one who uses it.

“All too often, I have seen users use the butt of a drill, where the battery is, as a hammer to tap something,” noted Festool’s Rick Bush. “Understandably, this is a convenient thing to do, but it does risk fracturing the case and/or rupturing battery cells.”

Beyond misuse, there’s no question that Li-ion batteries are susceptible to heat issues, which is why manufacturers put so many heat monitoring and controlling electronics into tools, batteries and chargers. Every company also stresses safety issues in their product manuals — which, unfortunately, many users ignore.

To start with, Li-ion batteries hate heat. Batteries shouldn’t be stored or used in excessively hot conditions. At best, a battery that starts out hot might simply shut down. At worst, it won’t function at peak levels, can age prematurely and can present a risk of fire. Batteries also don’t like it when foreign matter gets inside, especially conductive or corrosive liquids.

Every single manufacturer designs tools with heat and general safety in mind, tests batteries in all stages of the building process, and urges users to use the tool correctly.

“Manufacturers put a strong emphasis on users following product-use guidelines,” says Bosch’s Theron Sherrod. The trick is getting people to read the manual.

Milwaukee Tool recently surprised many in the industry by taking a proactive stance on battery safety by launching a voluntary information and education campaign. Working with the U.S. Consumer Product Safety Commission, the company has expanded the warnings and instructions of its current 18-volt M18 9.0Ah battery pack to address situations that could lead to a battery pack failure or other safety hazards.

In addition to including the expanded safety wording with the batteries themselves, Milwaukee has created a webpage with

the expanded warnings and instructions in their entirety, as well as a Frequently Asked Questions section at www.milwaukeetool.com/company/safetynotices.

What’s Ahead?

Will we see more of these high-voltage tools in the future? DeWALT’s Ward Smith promised that they plan to launch more 60-volt tools this year as part of a system expansion, while at the same time continuing to evaluate possibilities with their 120-volt system.

Meanwhile, ongoing tweaking of battery chemistries will undoubtedly show a steady improvement in Li-ion technology. Considering how much better Li-ion batteries are today than those powering cordless tools when introduced a bit more than a decade ago, it’s a safe bet the batteries of a decade from now will be even more advanced.

“Future technologies in battery chemistry, charging, discharge rates, capacities and larger and greater tool demands will continue to drive the industry,” says Rick Bush of Festool. “I would expect to see more and more cordless tools that mimic the corded tools they replace.”