One of the few constants in life is change. Whether we embrace it, or brace ourselves against it, change is bound to happen, regardless.

Jack Xu, president of Harvey Industries, has certainly experienced change in his business. But he’s also embraced the innovations and improvements that can come about through change, which even now are altering the kind of business he’s doing within the woodworking industry.

Eighteen years ago, he founded Harvey Industries in Nanjing, China, as an OEM supplier of metal-working machinery. Prior to that time, Xu had been in the business of trading metal-working machinery but not manufacturing it. He knew the industry well, but he also knew its shortcomings.

“I’ve always admired the high level of quality of machines made in the U.S., Japan and Germany. But back then, the quality of Chinese metal-working machinery was very poor,” Xu says. “Considering my background as a mechanical engineer, I knew Chinese machines could be made much better.”

Xu says he’s always considered himself to be a matchmaker of sorts, bringing the metal-working industries of his clients together with the Chinese factories who could supply them with the machinery they needed. Still, when he was just a trader and not a manufacturer, that matchmaking was difficult.

“There were times when I couldn’t face my colleagues in the West with the inferior products I had to offer them.”

So, Xu took matters into his own hands and set out to create a company that would raise the level of quality of Chinese machinery. But, the metal-working machinery business was an important revenue source, and Xu didn’t want to erode the relationships he already had in that business by launching a new brand and competing against his former colleagues. What could his new Harvey Industries make instead?

“We knew we had an advantage in cast iron, because China’s foundries manufacture so much of it,” Xu says. “I knew the best parts suppliers already. And I knew we would need to make machines that are assembled by humans and not robots. We couldn’t be big enough back then for robotic assembly lines.”

So, he and his business partner envisioned three alternatives: food processing machinery, textiles machines or stationary tools for woodworking. Any of the three could have been viable choices, so Xu let chance be his guide.

“We flipped a coin on it, twice. It came up in favor of woodworking, and that was as much fate as we needed to say, ‘Let’s do it!’”

In 2005, with a team of 30 employees, Harvey Industries began to manufacture woodworking machinery. At first, there was just a 10-in. cabinet saw and a planer, which Steel City Tools picked up when that company incorporated. But, with that initial success, and then a few other important contracts secured, the product line began to blossom. Over the past 12 years, Harvey’s woodworking machinery business has grown steadily, with the company now making band saws, various table saws, a wood lathe, dust processors, shapers and spindle motors. Xu credits the growth to Harvey’s high standards of manufacturing, some luck and his continued efforts to be a good matchmaker between supply chains and clients.

Currently, Harvey Industries does business with 105 countries, both as a metal-working and woodworking tool supplier. In 85 of them, the company sells as its own Harvey Industries label. For the others, Harvey serves as an OEM supplier, providing machines for around 50 different tool brands. He estimates that about one third of those machinery brands are found in the U.S., and several of them are major woodworking tool companies we use in our shops.

Just this year, Xu has moved Harvey Industries forward by designing a couple of innovative products that add to the company’s core line of metal-working and woodworking machines. You may have seen our recent video of the GYRO G700 Dust Processor. It’s a Harvey Industries “innovation” product, with features and efficiency unlike any other woodworking dust collector on the market. The company’s new T40 Turbo Midi Lathe uses a unique motor controller and has an especially heavy-duty build for a benchtop lathe.

There’s yet another new venture for Harvey Industries, where Xu is serving as a matchmaker between the Chinese government and some 12,800 colleges and universities. It’s an unlikely development that’s taken shape over just the past five years or so.

“China has had an export and infrastructure investment economy for a long time,” Xu says. “But cheap labor and an economy with more than 50 percent of its revenue based on investment isn’t sustainable. Even export is becoming risky, because costs are going up.”

The Chinese government’s answer to a more stable future is to shift the economy into more innovation-based opportunities. And the first step toward making that long-term goal a reality is to re-educate its students by changing the curriculum within higher education. The government is targeting colleges and universities.

“In China, traditionally students being given the answers to problems. Teachers teach that the solutions to the important questions of math, science and otherwise are already known,” Xu says. “Students aren’t encouraged to be creative … to come up with their own answers to new questions.”

One way the government has begun to encourage more creative thinking is to subsidize colleges and universities that add creative-based courses to their curriculum. Among those new course options is woodworking.

“We were doing a little business with higher education already, supplying a table saw or other machine here or there,” Xu recalls. “But our core business was in the hobbyist market, not the educational market. I didn’t take that segment of the market seriously.”

Then it began to dawn on him: in order for students to really learn woodworking, a table saw wouldn’t be enough. What colleges or universities need are fully-equipped shops and well-trained teachers to manage them. It would need to be a systematic approach.

“I’ve given this considerable thought over the past few years,” Xu says. “The logic is pretty simple: Creativity comes from the joined efforts of knowledge, imagination and hand’s on practice — elements woodworkers in other places already do so well.”

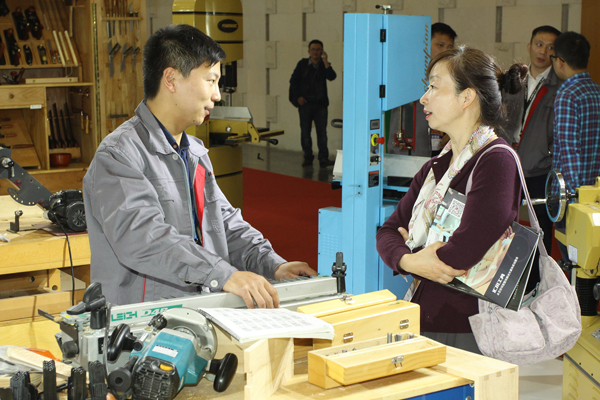

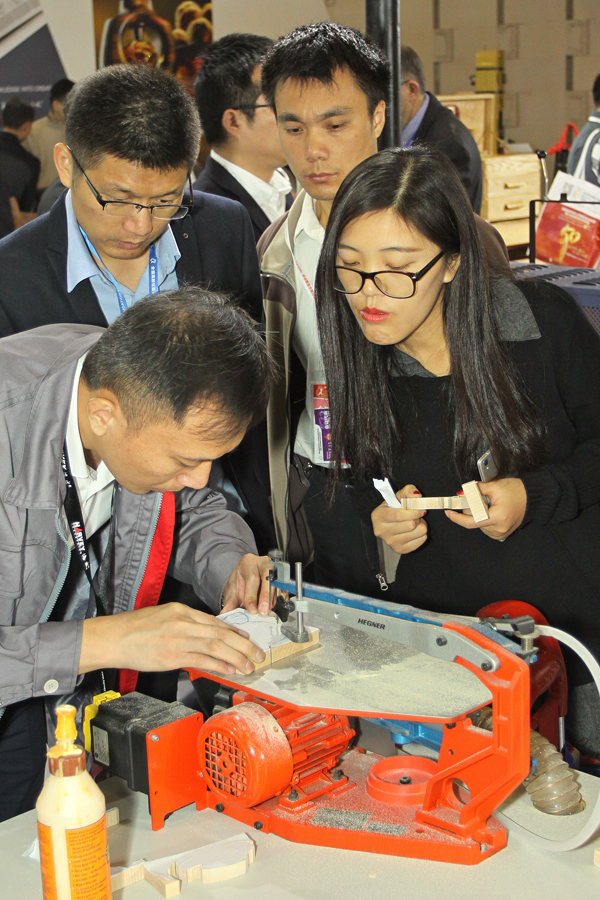

So Xu, and Harvey Industries, are now helping some 200 universities achieve these goals through what he calls “Creative Centers.” The company provides the institution with Harvey woodworking machinery, other high-quality hand and power tools, accessories, learning materials and training. The program is growing rapidly.

Harvey has already translated nine woodworking books from English into Chinese and published them. Xu also has spearheaded an effort to offer only the highest quality products into these Creativity Centers — many of which are imported from the U.S. and Canada. SawStop, Lie Nielsen, Veritas, Gorilla Glue, Kreg and Rockler are among the many brands being sourced for Chinese students to use in their college woodworking classes.

“There are Chinese alternatives for all of these products, but none of them are up to our standards for our Creativity Centers,” Xu says. “I think we must offer the highest-quality supplies right from the start, because the first things students use can influence their woodworking experience for the rest of their lives.”

Harvey Industries has also added an 8,000 sq.-ft. woodworking shop to its Nanjing factory. Here, college teachers are brought in for basics training in woodworking methods and tool use. The shop is staffed by four full-time woodworking trainers.

Aside from new opportunities in higher education, there’s a second new market for woodworking in China. For the first time in its history, the country is experiencing a growing middle class. Along with their new prosperity, some middle-class Chinese are turning to woodworking as an avocational interest. Xu says he services about 25,000 hobbyist woodworkers already. Woodworking clubs are also beginning to form to help bring woodworkers together. For instance, a new franchise called “M.Y. Lab” offers a membership-based “maker space” where woodworkers use the shop, tools and supplies to build their projects. They also receive skills training by M.Y. Lab staff. Xu sees new opportunities for Harvey Industries to provide these clubs with both machinery and other supplies, just like it’s doing for the educational market.

“Through woodworking education, we learn that there isn’t just one answer to every problem or question. There can be new answers, and even new questions! By being allowed to make mistakes and then solve them, that’s where learning happens,” Xu says. “I’m very proud to be helping Chinese students and hobbyists become better independent thinkers using our resources at Harvey Industries.”

Learn more about Harvey Industries by clicking here.