Offering smoother surfacing on complex grain, simple maintenance and quieter operation, these “Cadillacs” of the jointer world are long on convenience. We put six leading models to the test.

Frustrated over the hassles of setting conventional straight knives, I pushed my old 6″ jointer out the door 11 years ago and bought one of the then-“new” 8″ helical cutterhead models. I’ve never regretted it. Fixing nicked or dull edges is as easy as loosening screws and turning the little square carbide inserts to a fresh edge. No need for resharpening or hours fussing to get all the knives cutting on the same plane. Maintenance aside, I’ve also marveled at how well a shear-cutting helical head can make clean work of gnarly, interlocked grain. Tearout seldom happens.

Look through the models here, and I’ll anticipate your gasp. Yes, these 8″ jointers are expensive! But, once you have one, you’re set for a lifetime of quality surfacing jobs. And I’ll bet you won’t miss the old straight knives when the cutters need service. Here’s how these state-of-theart machines tested for me.

Baileigh IJ-883P

Street Price: $2,945

Weight / Motor Size: 540 lbs. / 3hp, 220 volt

Fence / Table Size: 5-1⁄2″W x 48″L / 8″W x 83″L

Table Height: 31-3⁄4″

Cutterhead Inserts / Rows: 36 / 4

Cutterhead Speed: 5,000 rpm

Web / Phone: www.baileigh.com / 920-684-4990

A jointer performs three crucial tasks: flattening, straightening and squaring faces and edges of workpieces. To do that well, it needs flat infeed and outfeed tables that are parallel to one another, both widthwise and lengthwise. It also must have a fence that can be squared accurately to the tables. The longer and taller these reference surfaces are, the better.

Baileigh’s aircraft carrier-sized IJ-883P has table and fence proportions in spades: it offers about 7″ more table length than any jointer here, and about a 10″ longer fence. Plus, at 5-1⁄2″ tall, its fence is the tallest — a real advantage for edge-jointing wide stock.

To evaluate all the jointers for table and fence flatness, I used a 50″ machined straightedge with +/- .003″ accuracy over its length and a set of feeler gauges. So, I used .003″ as my benchmark for what I’ll consider to be “flat.” (Keep in mind, .003″ is about the thickness of a sheet of office paper. I was picky.)

Under the straightedge, the IJ-883P had tables that not only were dead-flat along their length and width (measured at five places), as well as along both diagonals, but when the tables were leveled to one another, they were precisely coplanar along 83″ of length! Impressive.

The fence has a large ratcheting handle that makes it easy to adjust for squareness to the tables. I dialed that in with an engineer’s square right at the cutterhead area. Then, sliding the square to each end of the fence, it was square on the outfeed end but tilted away about .012″ at the top corner of the infeed end. Lengthwise, this fence was slightly concave, allowing a .025″ feeler gauge to slip underneath my straightedge.

But, regardless of a bunch of minuscule numbers, where rubber really meets the road is how flat and square a jointer can make a workpiece. So, I settled on a “real world” performance test for these machines: flattening and squaring a 7-3⁄4″- wide, 4-ft.-long piece of 8/4 poplar. And Baileigh’s IJ-883P had no trouble with that job: I set the jointer up for 1/32″ passes, and the board face became straightedge-flat and square. While its 36 carbide inserts did leave some very faint tracks on the lumber’s test face, I could only see them in strong raking light. The IJ-883P created the smoothest board surfaces of this group.

There’s much to like here. Its front-facing hand wheels with folding levers make the tables easy to adjust up and down, and the action is silky smooth. Similarly, a handwheel on top makes the fence easy to adjust laterally.

The jointer’s control panel has a helpful white light that shines to show it’s plugged in. Turn it on, and the IJ-883P’s 3hp motor muscles through wide hardwood. I was surprised that, unlike other jointers here, only one narrow V-belt delivers all that power to the cutterhead: most have two belts. But, Baileigh makes tightening it simple with a threaded adjuster. Other jointers here could benefit from that good feature, too — they involve loosening motor mount bolts and moving the motor.

Baileigh has only been offering woodworking machinery for four years, but it has a long tradition in the metalworking field, and that commitment to high quality is evident here. Even the edges of the tables are ground flat and smooth. Fit and finish all around is excellent. Priced just under three grand, this is a spendy jointer, but what a dandy it is!

General 80-200L HC

Street Price: $2,889

Weight / Motor Size: 572 lbs. / 2hp, 220 volt

Fence / Table Size: 4″ W x 38″L / 9-1⁄4″W x 74-7⁄8″L

Table Height: 32″

Cutterhead Inserts / Rows: 36 / 4

Cutterhead Speed: 5,500 rpm

Web / Phone: www.general.ca / 888-949-1161

Selling for about $100 less than Baileigh, General’s helical head jointer offers some similar features: it has front-mounted handwheels with folding levers for cranking the tables up and down. The fence is hand wheel controlled, too, for moving it back and forth. But, the table length and fence proportions are more modestly sized.

Unlike Baileigh’s “parallelogram” styling, where the machine’s tables move up and down on pairs of tilting parallel arms, this General is what’s called a “wedgebed” jointer: the tables slide up and down on dovetailed ways cast along the edges of the machine’s sloped, center bed. It’s the traditional style. Some will argue that a wedgebed requires more regular adjustment to level the tables end to end. I’ve not found that to be necessary on my wedgebed jointer after 11 years of regular use.

The 80-200L HC has precision ground tables that were within my .003″ tolerance lengthwise, diagonally and across their widths. They were also coplanar when leveled up, from end to end.

Once dialed in for square, this machine’s fence was flat along its center, lengthwise, but the top infeed corner showed a .005″ deflection.

When I set the infeed table for a 1/32″ cutting depth to run the poplar test, I found the table’s knurled locking handle kind of hard to reach; it’s tucked between the guard’s pivot post and the big handwheel. But, I tend to leave my jointer at the same cutting depth most of the time anyway. Not a big deal.

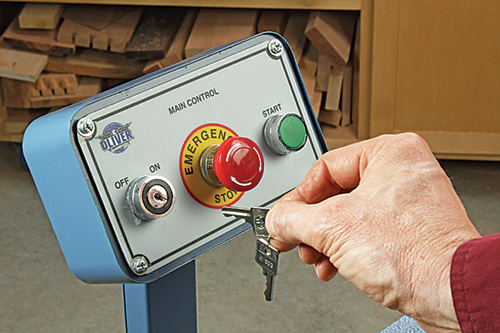

General provides an enormous “Off” button located on the infeed side of the base. It will help you shut the machine down with your knee — convenient when your hands are full. But, I found the control box a bit low for my long legs. You’ll need to bend over to start it, too, as the “On” button is nestled here. The switch is keyed, for extra security when you’re not around to monitor usage. It’s a good safety feature only General and Oliver share.

Turn it on, and the 80-200L HC is very quiet. Even when pushing stock through with a dust collector running, the ambient noise didn’t exceed 92 dB on my sound meter. That was true for all six jointers, and it’s a side benefit to the helical cutterheads. Their design makes them quieter than straight-knife styles. You should always wear hearing protection, of course, but at least these machines will be more tolerable in households with basement shops.

General’s jointer flattened and squared the poplar quite nicely. The face surface showed one slightly raised track, but it was otherwise smooth and ready for use. All in all, the 80-200L HC is an accurate, well-made machine.

JET JJ-8HH

Street Price: $1,939.99

Weight / Motor Size: 411 lbs. / 2hp, 220 volt

Fence / Table Size: 4″ W x 38-1⁄2″L / 9″W x 67″L

Table Height: 31-1⁄4″

Cutterhead Inserts / Rows: 36 / 4

Cutterhead Speed: 5,500 rpm

Web / Phone: www.jettools.com / 800-274-6848

Following on the heels of Grizzly, JET’s wedgebed JJ-8HH is also one of the more budget-friendly machines in this group. A careful check of its tables showed them to be extremely flat, straight and coplanar. Same goes for the fence: I found no evidence of a deflection in the casting from end to end, and it held an accurate square corner. Still, it has the same locking lever issue as Grizzly: release the fence to shift it across the table, and the lever tends to swing down and obstruct the fence’s travel.

The large table adjustment hand wheels are underneath — typical for most wedgebed joiners — and they turned more stiffly than front-mounted wheels. The machine’s rather tiny T-style table locking levers aren’t as comfortable to tighten and loosen as other knurled styles or longer ratcheting handles. But, these are minor gripes if you don’t change the table settings very often.

Tightening the JJ-8HH’s twin drive belts will be necessary at some point when they stretch, and you’ll need to do it when setting up the jointer for the first time, too. It’s not easy. The motor sits on a pivoting platform, and tensioning the belts requires loosening four bolts that face inward in the base, making wrench access difficult. General and Laguna’s jointers are similarly challenged.

On the plus side, the JET JJ-8HH did a terrific job of surfacing wide poplar. There was some amount of fine washboarding on the face but no evidence of uneven inserts. The board’s test edge was rendered flat and square.

JET offers two mounting options for the control box. If you prefer the ability to “knee” the machine’s paddle switch to turn it off, you can position the post low on the base. Or, bolt it near the top of the base so the control box will be above the infeed table instead. Good convenience.

In the process of examining the power switch, I noticed that it’s the only nonmagnetic type here. Why does that matter? Well, in the event the jointer is running and your shop’s power goes out, the machine won’t turn itself off. Once the power comes back on, it will start running again. A magnetic switch would be better for safety.

While the JJ-8HH has shorter tables than other jointers here, it delivered the goods for doing accurate surfacing work. Like the rest of the test group, it comes with some spare inserts and screws for them, Torx screwdrivers and a variety of wrenches. A pair of pushpads that the rest provide would be helpful “extras” here, too, but those aren’t included.

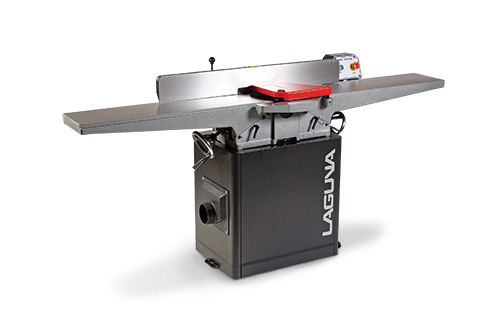

Laguna MJOIN8012-0130

Street Price: $1,999 or $2,299 (w/ Leeson motor)

Weight / Motor Size: 510 lbs. / 2hp, 220 volt

Fence / Table Size: 4-3⁄4″ W x 38″L / 9-1⁄4″W x 75″L

Table Height: 32″

Cutterhead Inserts / Rows: 54 / 6

Cutterhead Speed: 5,600 rpm

Web / Phone: www.lagunatools.com / 800-234-1976

While a couple of these jointers have 3hp motors, I think it’s more than necessary for surfacing 8″-wide stock. A 2hp motor is plenty powerful, and Laguna is proud of the motor it supplied on my test jointer. It’s an American-made Leeson, which company spokesman Benjamin Helshoj says draws much lower amperage than comparable Asian motors. I wasn’t able to test that claim. Upgrading to the Leeson will cost $300 more than buying the jointer with an Asianmade motor instead.

Laguna’s infeed and outfeed tables were within .003″ lengthwise, widthwise and diagonally, and when cranked level with one another, they were also dead-flat from end to end. I squared up the fence at its midpoint near the cutterhead, then checked the ends for square. They deflected about .005″ off of square — at the bottom of the infeed end and the top of the outfeed. But, it’s a tiny amount of deviation and more than accurate enough for woodworking.

Another impressive feature, from Laguna’s standpoint, is its ShearTec II cutterhead with 54 inserts. That’s 18 more carbide teeth than most, which allows this cutterhead to have six rather than the typical four rows of edges. More rows means smaller bites per knife, amounting to smoother cuts and longer edge retention.

Though impractical for this test, it would be interesting to see if a 54-insert cutterhead would outperform a 36-insert head over time, in terms of sharpness or cutting quality, before the inserts would need to be rotated. But, in this limited test period, what I can say is the ShearTec II delivered flat, smooth surfaces on my poplar test piece. Were they smoother than Baileigh’s test cuts? Not quite, but it’s a silly comparison, really. They only need to be flat, straight, square and smooth enough for planing, other machining or assembly. Laguna’s results passed that criteria with ease.

I’ve already alluded to this jointer’s fixed direction casters inside the base. The infeed-end wheels lock with star knobs near the bottom. If these wheels swiveled, it would be a more welcomed standard feature. Even so, the ability to roll 500+ pounds of heavy metal is helpful, no matter what. And you won’t have to buy a mobile base.

Laguna’s MJOIN8012-0130 delivered a strong performance for me. If you decide to forgo the Leeson motor, you could buy this jointer for about JET’s price. Between the two, Laguna’s longer tables, toothier cutterhead and built-in wheels give it a richer set of features than JET.

Oliver 4230

Street Price: $2,545.75

Weight / Motor Size: 572 lbs. / 2hp, 220 volt

Fence / Table Size: 5″ W x 38″L / 9-1⁄4″W x 74-7⁄8″L

Table Height: 30-1⁄2″

Cutterhead Inserts / Rows: 54 / 6

Cutterhead Speed: 5,500 rpm

Web / Phone: www.olivermachinery.net / 800-559-5065

The rugged design of Oliver’s 4230 may remind you of your school shop days, where woodworking machines seemed made to last forever. The company mounts this jointer on a flared steel base for maximum stability, then sets that on a beefy cast-iron skirt. Durability, not portability, is the goal here. The fence moves back and forth smoothly on a massive rack-and-pinion tube assembly with a metal hand wheel. Long handles lock it in position and square it to the table. It’s the stoutest design of this test group.

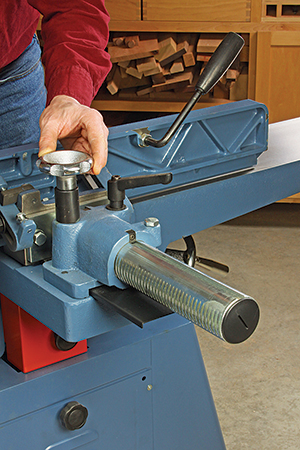

When prepping the machine, I appreciated that the motor belt tensioning system is simple: tighten one nut on a threaded shaft to take up any slack, and lock a second nut against it to hold the setting. It’s a helpful detail.

The control panel features a keyed lockout that I’m sure my high school shop teacher would have appreciated. Its “On” button glows green when the machine is running (as do Grizzly’s and Laguna’s). Instead, I wish the green light were constantly on, so you’d know the jointer is still energized, even when it’s not running.

Oliver’s infeed and outfeed tables were flat and straight, but they weren’t quite in the same plane: both the infeed and outfeed tables tipped down from the cutterhead at their outboard ends: .014″ on the infeed end and .016″ on the outfeed end. But, the poplar still came out flat and straight enough to satisfy my straightedge.

Likewise, when squared to the table at its midpoint, Oliver’s fence showed a slight twist over its length. The top corner of the infeed end deflected .004″, while the bottom corner of the outfeed end deflected .006″. Even so, the poplar’s face and jointed edge were square — proof that a little deviation is definitely not a deal breaker.

Oliver outfits the 4230 with a 54-insert cutterhead, like Laguna. All those chips of carbide produced nearly flawless surfaces on my test stock with just the lightest hints of track marks. In terms of overall smoothness, Oliver and Laguna were about evenly matched.

There isn’t much I’d change on this seemingly bulletproof jointer. The control panel is pretty close to the fence’s tilt-lock lever, and it can impede the lever’s throw. Oliver also doesn’t include a plug on the cord (and neither does JET). But those are easy to wire yourself.

You Can’t Go Wrong

These jointers satisfy their woodworking purposes well, and they’re built to go the distance. While your budget may limit the choices here, any of these machines would be a fine addition to a serious shop.