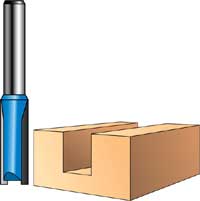

I want to plunge route, going all the way through the wood panel in stages. Is there a special straight bit that I need?

John Brock: You want one that has sharpened cutters that go across the end. However, a much better choice is an up-spiral bit designed for plunge cutting so the chips will clear from the blind hole, and the sides of the hole will be shear cut by the spiral flutes. I use HSS or solid carbide end mills. These are designed for cutting metals but do an outstanding job on wood.

John Swanson: The router bit must be for plunging; i.e., with cutting surfaces on the bottom. When cutting through in stages, an up-cut bit will clear the debris much better.

Richard Jones: Look for a router bit with a bottom cutthere’s a gap in the center at the end of the cutter. You need a slight upshear style to go with the bottom cut where the flutes eject the chips better. Also, consider using an up-cut spiral bit. They have a tendency to pull out of the collet so need to be firmly installed.

Carol Reed: Use up-spiral bits to plunge cut. The waste is removed from the cut efficiently, allowing the cutter to cut cleanly and cooler. When bits overheat, they become dull amazingly fast. The spiral bit also shears wood fiber yielding a superior quality cut.

Mark Hensley: I use a spiral cutter.