Take a look at the SuperMax drum and brush sanders, and you are bound to find them rather reminiscent of the upper end of the old Performax line. There’s a good reason: That is precisely what they are. Although the story of how this company came about is slightly convoluted, its roots go back to the Performax company. For that reason, a quick trip back in history will help us understand exactly what SuperMax is today.

Garry and Donna Green started the Performax company in their Minnesota garage back in the mid-1980s. Their first tool was a sander that attached to the column of a radial arm saw (RAS), an accessory to allow those who could not afford a commercial sander to turn their RAS into a credible drum sander. Garry developed it because he was building a bar and needed it for himself, but soon friends and family saw it and wanted one also.

Every June, the Minnesota Inventors Congress, which bills itself as the “oldest and most prestigious” convention of inventors in the world, holds its convention in Redwood Falls, Minnesota. Garry and Donna took their invention there and won a couple of awards for it. After that, they were overwhelmed with orders. Garry quit his job with the Army Corps of Engineers, and he and Donna started building their first model, the “Performax S/T,” in their garage. It sold for about $150.

Back in those days, the radial arm saw, which has since fallen into disfavor, was very popular. For a surprising number of woodworkers, this versatile, but somewhat dangerous. workhorse was the first major power tool to grace their shop. Performax appealed to a legion of serious hobby woodworkers and small shops that could not justify buying a wide belt sander, but who owned a RAS.

Their initial venture grew to the point where they had a 20,000-sq.ft. factory, housing over 30 employees making about a dozen models of free-standing drum and brush sanders, both open-ended and closed-end, along with the original clamp-on model. Among those 30 staff were Warren Weber and Bill Schroeder, two men who are about to figure very prominently in our story.

In 2001, JET bought Performax and moved it, along with all the employees who agreed to stay, to a larger facility in Minnesota, and owners Garry and Donna retired. However, after a couple of years, JET moved the manufacturing out of Minnesota. They started making the smaller models offshore in Taiwan, and the larger models in Nashville, Tennessee. Employees willing to relocate were offered jobs, but of course, not all of them cared to move.

Bill Schroeder, who had been Performax’s general manager, moved to the JET plant in Auburn, Washington, and not long after, to Nashville. Warren Weber, who had started with Performax in 1988, remained in Minnesota. Apparently, Bill’s heart stayed there as well, and he eventually moved back to Minnesota. The two men joined forces again in 2005 to create SuperMax.

“We saw the need for quality, drum and brush sanders for small cabinet shops,” recounted Weber, “and felt that JET had more or less ignored that market segment in favor of promoting their smaller machines. They stopped taking the larger machines to trade shows and were not advertising them in the major media. Bill and I approached WMH, the parent company of JET and asked to buy back the rights to manufacture the larger machines. That meant anything with a drum larger than 24′, including all the closed-end machines. WMH agreed to sell, but kept the Performax name, retaining only the rights to make the three small, open-end sanders, all of which are made overseas.”

Bill and Warren then established SuperMax right back where it all began, in Minnesota. “We got a facility, contacted some former Performax employees who had chosen to stay here and opened a factory with a dozen employees,” Weber said. “That gave us an already trained and experienced staff from day one. It felt wonderful getting the old group together, since they all enjoyed having worked for Performax and were missing it. Along with the rights, we also bought the inventory of parts, so manufacturing was seamlessly continued.”

Warren frequently flips back and forth, using the terms “we” and “us” to mean both the old Performax company and the new SuperMax, something quite understandable considering his long tenure with both. It gives one the feeling that the company is merely going through another iteration, with much of its staff and all of its history intact.

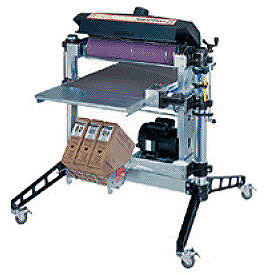

“We started making sanders ranging from a single drum unit 25″ wide, all the way up to a 50″dual drum model and two brush sanders as well. Presently, the 37″ dual drum sander, a size right in the middle of the line, is by far our best-selling item. It competes head-to-head with a wide belt sander but costs considerably less. In addition, it allows you to sand thinner, thicker and shorter pieces. You can sand as thin as 1/32″ up to 12″ thick and can feed pieces as short as 3 1/2″ long.”

One handy item they offer on almost all models is the patented SandSmart feature. “All our conveyors are variable speed,” Weber explained. “SandSmart monitors the load on the drum and automatically slows the feed conveyor if it encounters a high spot or extra resistance, then speeds it up again when the pressure releases. This prevents burning of the wood, stalling the motor, or tearing the belt.

“All the units are small enough and light enough that they can be put on casters, which come standard on some models. The fact that they can be moved around is a real boon for smaller shops. Unlike a wide belt sander, our tools do not need to be hooked up to an air compressor, which adds to their portability.”

Warren is quick to point out that listening to their customers is a prime directive at SuperMax, and for good reason. “All our changes and improvements are inspired by feedback from our customers, which is why we are so committed to attending shows and staying in contact with them. A larger brush sander, to be introduced later this year, is a good example of a tool that was requested by woodworkers, as is the SandSmart feature.”

They also go out of their way to make it easy to find their tools. “We have local distributors all over North America,” said Weber, “and locations in Australia and the UK. You can find one by going to the web site, or calling the company. While the website only lists those that stock the full line, we can direct you to many more that carry some portion of our product line if you call us. Any dealer, if they choose, can also order whatever model you want.”

Incidentally, SuperMax is the name of the tool line, but not the company. The actual company name is St. Joseph Tools, named after the patron saint of woodworkers. The faint image on their home page to the left of the name is a rendering of St. Joseph instructing Jesus in the craft of woodworking.

If that’s not a celebrity endorsement, I don’t know what is.