Choosing the best saw blade raises a lot of good questions.

- What’s the best table saw blade or miter saw blade?

- How many teeth should a blade have?

- Does a thin kerf or regular kerf make a difference?

- Do blade coatings make a difference?

- When should I sharpen my saw blade?

- How do I clean my saw blades?

Using a good quality saw blade can sure make woodworking more enjoyable. and often we spend a considerable chunk of change on them. We expect top-notch performance and long life from that investment. It only makes sense that questions come up now and then about how to choose, use and maintain blades properly, and you write in for our help. I think blade manufacturers are really the best sources for those answers, so I’ve rounded up some common FAQs that come into our offices and directed them to the experts at Amana, Forrest, Freud, GUHDO, Infinity and Irwin Marples. These folks were happy to share some nuggets of wisdom for our benefit, and some of their feedback may even surprise you. I hope this article serves as a good quick reference for those recurring questions you might have about your blades.

Saw Blade Buying Tips

What do I need to know about blade tooth options?

Saw blades are optimized for fairly specific cutting applications and tools, and their carbide teeth are engineered precisely to suit the purpose. There are three main tooth shapes: beveled edge, flat-topped or chamfered at the corners (called “triple chip”). Beveled teeth alternate left and right at a range of different angles, depending on the blade, to cut cleanly and quickly. Flat-topped teeth are used to clear away the remaining waste behind a group of beveled teeth on a combination blade or for fast stock removal on ripping blades. Triple-chip teeth are more stout than pointy beveled teeth and take smaller bites. You’ll often find them on blades designed for cutting abrasive or chip-prone materials like melamine, laminates, solid surface, plastics and metal or for fine crosscutting.

Tooth geometries are very complex. Besides the top grind that establishes the overall tooth shape, there are shear and clearance grinds to boost performance even further. Space just doesn’t allow for full explanation here. But one practical aspect to keep in mind when choosing a specific blade is hook angle. In lay terms, it’s the degree to which the teeth tip forward or backward on the blade body. Teeth oriented in “positive” hook angles lean forward to cut more aggressively and quickly. Teeth canted to “negative” hook angles tip backward to withstand greater abrasion while leaving a smooth cut. Hook angles range from 20° down to -5° or more; positive is typically used for ripping or general cutting and negative is reserved for slower, fine crosscutting applications and when sawing composites.

If I spend more and buy more teeth, do I get a better blade?

This is a complex question, because bargain basement priced blades typically won’t deliver the results and long-term durability of more expensive, premium blades. On the flip side, an expensive blade with lots of teeth in a geometry that isn’t suited for the way you’re using it won’t meet your expectations, either. More teeth doesn’t make a blade “better.” Manufacturers agree that we should benefit from their expertise: follow the tool and material suggestions for which the blade is designed in order to use it properly. One blade does not suit all jobs.

OK then, so what are the best blades for my table saw, miter saw and circular saw?

Blade experts tell me that the best compromise for both smooth ripping and crosscutting on a table saw is a 40- to 50-tooth “combination” blade. Depending on the manufacturer, this might mean the blade has alternating top bevel teeth (ATB) or has ATB teeth with an intermittent flat-topped or triple-chip raker tooth (ATB + R). For miter saws, if you use the saw for general-purpose cutting where absolute smoothness isn’t critical, choose a 40- to 60-tooth ATB grind with a positive hook angle.

But if glass-smooth finish cuts on moldings and other fine work is what you want, switch to an 80- to 100-tooth “hi-ATB” grind (where the teeth are ground to extra-steep cutting angles) with a shallower hook angle, ranging from +10 to -5 degrees. In terms of circular saws, we use these tools for a broad gamut of cutting jobs, but two blades can cover the yeoman’s share of tasks: use a 24- to 30-tooth general-purpose ATB blade for rough cuts and construction lumber. Swap that out for a 40- to 60-tooth ATB blade for clean cuts in plywoods, MDF and melamine.

The Truth About Saw Blade Thin Kerfs and Coatings

Why are there so many thin kerf blades these days?

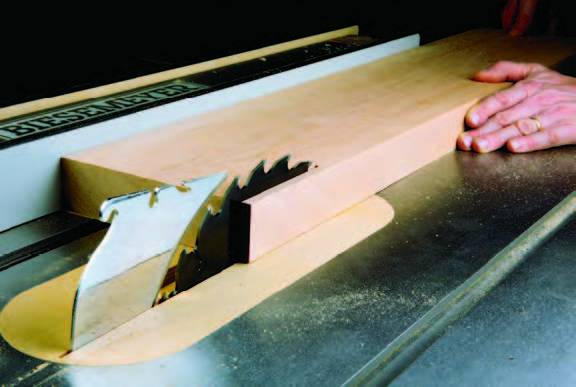

As miter saws and portable jobsite table saws have grown in popularity with both woodworkers and contractors, the industry is engineering thinner blades with narrower teeth to suit these lower powered tools. A thin blade requires less energy from the motor to do its work.

But, the experts agree that we should also consider thin-kerf blades to be excellent choices for heavier-duty saws, too. They remove less material than regular-kerf blades — a benefit for both your wallet and the environment when working with expensive or precious figured woods and exotics.

Thin-kerf blades also produce less sawdust for a cleaner, healthier shop setting. I was told that advances in blade metallurgy and CNC machining make it possible to create thinner and lighter blade bodies without compromising stiffness or cutting performance. So, don’t shy away from choosing quality thin-kerf blades: today’s premium options are suitable for every saw we use.

Do blade coatings matter?

On low-cost, “disposable” blades, sometimes coatings are nothing more than paint, I’m told. But, coatings of chrome, a Teflon® derivative or a blend of Teflon and metals such as nickel or aluminum definitely serve important purposes and are part of the blade’s design. For one, they reduce friction to keep the blade body and teeth from overheating, which can lead to warping, accelerated tooth wear and pitch buildup. Coatings also prevent corrosion and make blade deposits easier to clean away. Good coatings extend performance and longevity.

Saw Blade Maintenance Tips

How can I tell when my blades need sharpening?

The experts echo what you’ve probably already guessed by experience: if cuts are harder to push through and the saw labors, the teeth are probably dull even if you can’t see it with the naked eye. Increased burns and swirls on the wood are telltale signs, too. Of course, if any teeth are chipped, it’s time to send the blade in for sharpening, but if the teeth all seem to be intact, try thoroughly cleaning your blades first to see if that improves their performance.

Is sharpening worth the cost?

Yes. Manufacturers outfit pro quality blades with thick teeth so that they can be resharpened five to 10 times before the teeth are spent. If you’ve never sent a blade off for sharpening, here’s what may surprise you: the experts say it typically only costs around $20 plus shipping to service a 50-tooth blade. That’s a bargain compared with replacing the blade and spending three to six times as much. But, you need to start with thick teeth in the first place and then choose a quality sharpening service for best results; blade companies often can recommend authorized sharpeners to keep your blade arsenal in tiptop shape.

Do dirty blade teeth wear out faster than clean teeth?

They do, say the blade gurus, and here’s why. Pitch on the teeth and blade body creates friction, and friction creates heat. That heat becomes extreme at the cutting edges, where it can break down the carbide on the molecular level. As pitch builds up on all the contact surfaces of the tooth, the problem just compounds itself, exacerbating heat buildup and reducing the ability of the teeth to cool themselves. Pitch deposits also can throw the blade off balance like a car tire, where wobbling at the rim will lead to poor cutting quality and yes, even more heat buildup. A clean saw blade dissipates heat more evenly and spins true. So, an occasional cleaning is definitely worth the effort.

What’s the best way to clean a blade?

There are many specially formulated blade cleaners on the market, and that’s what we should use. The manufacturers agree that oven cleaner or other strong chemicals are altogether bad choices, regardless of how well they may seem to work. You wouldn’t clean a prized shotgun or the chrome trim on your car with harmful chemicals, so use the same reasoning with your expensive saw blades. Strong acids and bases are too caustic for this application; they can deteriorate the blade coating and weaken the cobalt that binds the carbide particles together. Even if you can’t see the results of chemical damage from using the wrong blade cleaner, that doesn’t mean it isn’t happening.

Neutral pH cleaners are best, say several of the experts I asked. Even a mild dish detergent and warm water can clean off pitch deposits, so long as the blade is coated to protect against rust. Soak the blade until the deposits soften up, then gently scrub the teeth clean with a nylon- or brass-bristle brush. Most of all, be patient. You may have to soak, scrub and then repeat the process, but eventually, all of the baked-on crud will come off. Then dry the blade and apply a rust preventative spray or oil.

Quality blades can be outstanding performers. With some sensible know-how from the folks that live and breathe blades, we can reap every bit of benefit from our saws.