It’s hard to imagine a correlation between fingernail polish, World War II and high quality woodworking finishing products, but that’s how Briwax International got its start. I recently spoke with JaLea Himes, Vice President of Sales and Operations of the company’s North American Division, who put the pieces of that puzzle together for me and provided an overview of Briwax’s unique history.

As the smoke was still clearing from post-war England, Jack Bollom—an entrepreneurial Brit—and his buddy were deciding how to transition from being soldiers to businessmen. The two set out to manufacture women’s fingernail polish in England, but while the dyes and pigments were available, the country was fresh out of acetone. So much for fingernail polish. Instead, they bought linseed oil, set up shop in an old barn and started churning out a line of brightly colored house paints. The paint turned out to provide such a visual, emotional lift during the reconstruction of England that the Bollom Group flourished. As time passed, the company branched out into coatings for the film and textile industries, as well as fire-retardant paints.

Then, in 1961, Bollom purchased Henry Flack Ltd., a manufacturer of natural waxed-based wood coatings, and Briwax was born. To this day, the Briwax product line is still manufactured exclusively in the U.K., but its proud reputation and premium product offerings have, of course, spread worldwide. In fact, Briwax products were awarded the Royal Warrant — the Queen of England’s highest seal of approval for quality. Two of Jack Bollom’s sons still own the company and, since 2007, have focused its energies entirely on developing and expanding Briwax woodworking products.

If you’re a professional refinisher, conservator or antiques dealer, you’re probably already using Briwax furniture finishes, cleaners and wood dyes in your work. But, for those of us who don’t know as much about Briwax products, it might have to do with where you shop for your finishes. You won’t find Briwax sold in “big box” chain stores here in the States. JaLea says the company prefers to limit distribution to smaller independent hardware stores and other woodworking supply companies such as Rockler Woodworking and Hardware. That way, knowledgeable store owners can help woodworkers find the right Briwax products for their needs.

And, as I’ve come to learn, there’s quite a range of offerings! Briwax manufactures six different silicone-free wax products to suit a broad range of woodworking and other applications. Here’s a brief introduction to each of them:

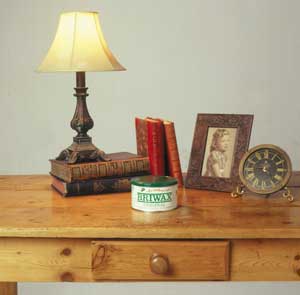

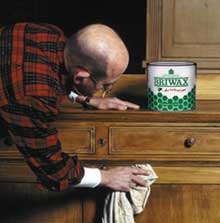

Briwax Original is a blend of beeswax and carnauba, with an emulsifying solvent, formulated as a soft paste. JaLea explained the solvent not only blends the waxes but also serves as a gentle cleaner to remove grime from existing finishes. Briwax Original can be used as a stand-alone, easy-to-repair finish on bare wood or as a protective final coat over another finish. It’s sold as clear and in nine different pigmented wood tones, where it can double as both a stain and a finish. The coloring also works well to hide small scratches in finishes that are in otherwise good repair but need some minor touch-ups.

Sheradale Wax contains a blend of waxes, plus paraffin, which provides higher water resistance and sheen than Briwax Original. It’s a good polishing option for lacquer and other film finishes.

Liming Wax creates a pickling effect when used on open-pored woods such as mahogany, ash or oak. Here’s a classic way to highlight wood grain. (For a practical example of liming wax in action, see Betty Scarpino’s dye and liming wax finishing technique on p. 34 of the December 2008 print issue of Woodworker’s Journal.)

The company’s Staynwax is a water-based sealer that comes in 16 oz. bottles in the consistency of thinned paint. It can be ragged, sprayed or brushed onto wood, then buffed to impart a smooth, velvety texture quickly and easily.

Marble Wax, a blend with a higher concentration of carnauba, is formulated to provide a water-resistant finish for marble and stone countertops and sinks as well as terra cotta or quarry tile. It buffs to a lower sheen but with more durability than softer wax offerings.

Briwax Natural Creamed Beeswax consists of just three ingredients: beeswax, linseed oil and turpentine. It’s suitable for any type of wood where a clear, satiny finish is desirable. If you’re looking for a simple, low-luster topcoat to impart a close-to-the-wood effect, here’s a finish to try. Or, buff it out to a higher sheen.

In addition to wax-based coatings, Briwax offers a number of other products beneficial to our finishing efforts. The company makes premixed, water-based aniline dyes in five primary colors. You can blend them to create any stain color you prefer or use them to tint other water-based dye stains. Briwax sells three colors of felt-tipped dye pens and five shades of carnauba-based wax filler sticks for concealing scratches or filling nail holes. Furniture cleaner, Danish and teak oils, five colors of grain filler, a friction polish for turnings and shellac sanding sealer are also available. Oil-free steel wool rounds out the product offerings.

Even though the company focuses on woodworking applications, JaLea says they receive calls frequently from folks who find creative new ways to use these products. “People use Briwax over painted finishes, untreated metals, leather, Venetian plaster moldings, pottery, for faux finishing or to age a new finish to mimic an old one. We encourage that kind of creativity. Briwax is only limited by your imagination.”

And creativity continues to drive new innovations. In a few weeks, Briwax will roll out a new product called EZ-Swipes. A first in the finishing industry, according to JaLea, these citrus-based hand wipes should help to make our cleanup tasks easier. They’re intended to remove dye or pigment stains from skin, as well as latex paint, oil and other petroleum-based finishes. The wipes will be available in 35-count dispensers.

Although the Briwax family of products is currently sold primarily through distributors, you can learn more about them and place an order by calling the company directly at 800-527-4929. And, within the next three to six months, their website (www.briwax.com) will be expanded to offer easy, online ordering as well.