Woodworking’s not much fun when the space you’re working in feels more like an oven than a shop. Luckily, there are many ways to make a shop cooler and more comfortable.

Although we’re capable of traveling to the far, frozen reaches of outer space as well as trekking across scorching deserts, we humans actually have a relatively narrow range of temperatures and humidity levels at which we’re truly comfortable. And it’s important to feel comfortable when you’re making sawdust: you need to keep your concentration when using power tools.

Keeping the mercury and moisture level down in the workshop not only makes woodworking a more pleas- ant pursuit, but it also helps prevent problems like tool rusting and lumber warping and checking. Excessive heat can also ruin adhesives and finishing supplies, as well as cause problems when gluing or applying finishes.

I recently delved into methods for keeping a shop toasty warm (see my article “Best Ways to Heat a Woodshop“). Now it’s time to explore some strategies for making your shop a cool place to work when temperatures climb. There are basically three ways to make your shop a cooler place:

1. Keep the heat from coming in.

2. Get the hot air out and replace it with cooler air.

3. Condition the air inside the shop to make it cooler and drier.

Fortunately, there’s a lot more you can do to put high temperatures in check beyond simply switching on a power-hungry air conditioner.

Shade Trees, Vines, Etc.

One way to help keep your shop space cool is to prevent heat from getting into it in the first place. Having good insulation (which we’ll talk about in a moment) is the most obvious way of accomplishing this, but there are several other things you can do to reduce your shop’s heat gain.

One option to keep the heat out is to utilize shade trees, bushes and vines. Any plants located near your shop that provide a good deal of shade can keep a shop noticeably cooler and are a very “green” alternative to using electric cooling devices. If your shop lacks nearby trees or large bushes, consider adding a trellis to the south-facing side of the building and training a quick-growing vine to climb onto it. It’s best to choose a type of vine that provides good shade coverage, yet loses its leaves in the winter (the same goes for bushes or trees planted near the shop). This will allow the sun to shine on your shop in the winter, to help keep it warmer.

Awnings and Blinds

Installing awnings over door- ways and window openings can reduce solar heat gain in the summer by up to 65% on south-facing windows and 77% on west-facing windows. Awnings made from acrylic and polyvinyl laminates are water-repellent and resist fading and last much longer than traditional canvas awnings. Although they are more expensive, retractable awnings are a good choice, as you can adjust them to provide just the amount of shade you desire — large ones can even shade the entire side of a shop and/or create a shady spot for working outside. Leaving them retracted during winter helps prolong fabric life as well as allowing the warming sun in.

Interior window blinds are not as effective as awnings, but can help reduce heat gain for windows that are exposed to direct sun. On the downside, they collect dust: metal or plastic Venetian-style blinds are hard to clean, and fabric drapes and paper roll- up shades may present a fire hazard.

A better alternative is to treat windows that receive a lot of sun with a high-reflectivity film. Silver, mirror-like films are more effective than the more transparent colored films, and you can apply them yourself. On the downside, they do reduce interior light and make it harder to see outside. Plus, you must take more care when cleaning them, and they can create harsh glare to areas outside the shop.

Pale Paint and Roofs

If you live in a really hot climate (think Arizona desert), painting your shop white or a light tone and having a reflective or light-colored roof can help reduce heat penetration by up to a few degrees. That’s not much, but every little bit helps, especially if you ultimately run an energy- hungry air conditioner for long periods of time just to bring shop temperatures down to comfortable levels during the summer.

Insulation

The single most effective way to keep heat out of the shop is to insulate it well. Insulation makes it harder for heat to penetrate walls and ceilings, as well as (of course) keeping heat in during cold days.

There are two basic ways of insulating a building: adding thermal mass and creating an insulative boundary. Thermal mass is usually found in the form of thick, dense walls that don’t conduct heat well: think of how cool it feels inside a stone castle or down in a basement or cellar, where the earth itself provides thermal mass. It’s not practical to replace walls in an existing shop, but if you’re planning on building a new shop in a really hot climate, consider using concrete block, adobe and other masonry construction materials. It’ll cost more upfront, but you’ll save on energy bills in the long run and have a much more comfortable place to do woodworking.

You can also add good insulation to an existing shop. There are many insulation materials suitable for residential construction, including fiberglass rolls and bats, rigid foam and fibrous boards, spray foams, etc., some of which are easily installed. Additionally, there are blow-in insulating materials, such as cellulose, mineral wool and fiberglass, which can add insulation to existing sheetrocked or paneled walls and spaces too difficult to insulate with other materials. You can rent a machine and blow in the insulation yourself, or hire a specialized contractor to do the job for you (link to more information on insulation materials).

Showing you exactly how to insulate your shop is well beyond the scope of this article; there is plenty of reference information in magazines and books or online. It’s also good to consult with a professional insulation contractor, even if you plan to do most of the work yourself.

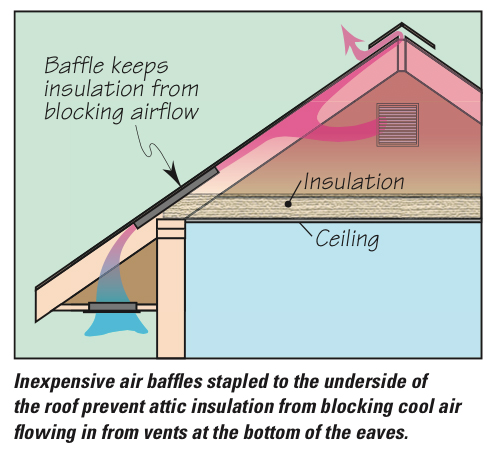

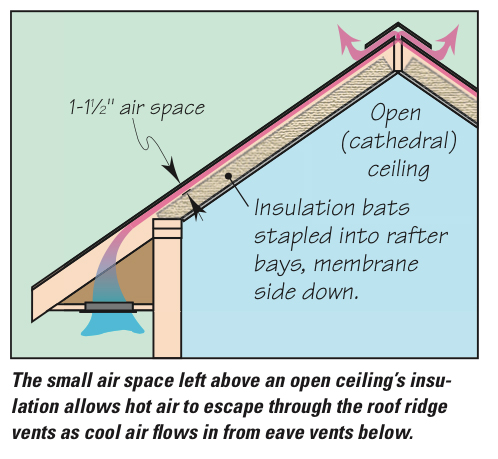

However, I can warn you of a couple of common mistakes woodworkers make when insulating their shops: 1. When adding thick insulation between the joists above a sheetrocked ceiling, take care not to block the attic’s eave vents (see the below). The vents allow cooler air to flow into the attic to replace hot air escaping from the gable or roof ridge vents. To prevent this problem, it’s easy to install air baffles, as shown in the Drawing. 2. If your shop has a cathedral style open ceiling with exposed rafters, don’t just stuff insulation between the rafters! It’s best to leave about 1″ to 1-1/2″ of clear space between the top of the insulation bat and the underside of the roof sheathing. There must also be an eave vent at the bottom and a ridge vent at the top of each rafter bay (see the Drawing). This allows hot, moist air that would otherwise be trapped above the insulation to escape. You can buy special cathedral ceiling bats, which are thinner than usual fiberglass bats or rolls with the same R value (the higher the R number, the greater the insulative value): 8-1/4″ thick (R30 rated) for 2×10 rafters; 10″ thick (R38) for 2×12 rafters.

Doors and Windows

You can reduce heat infiltration by fitting your shop with better insulated doors, windows and skylights. Exterior doors made of steel and fiberglass both have foam cores that reduce heat transfers somewhat better than wooden doors (steel doors and frames are also less susceptible to break-in).

For maximum benefit, look for doors that are Energy Star certified. Larger barn- and garage-type doors also come with foam cores that supply varying degrees of insulation, as specified by their R value.

Another way to reduce heat is by fitting windows that conduct heat less readily. Many new windows (and skylights) are labeled with energy saving information, including a “U-factor,” which indicates the window’s thermal conductivity. A lower U-factor number indicates a better-insulating window (the inverse of R value). Double-pane windows insulate about twice as well as single-pane windows, and the window frame material can also affect its insulative value, with wood and vinyl frames having lower U-factors than aluminum frames.

Getting the Heat Out

Once warmer air has collected inside your shop, your main options are to cool it (we’ll talk about that shortly) or exchange it for cooler air outside the shop. Simple ventilation is the easiest way to get rid of warm inside air and, if you live in a moderate climate, may be the only means of shop cooling you’ll need.

If your shop’s in a location that gets an afternoon breeze, you should be able to cool it down by opening windows or doors on the side the breeze is coming from, as well as opening a skylight, window or vent on the opposite wall to let the hot air out. If the breeze is weak (or nonexistent), you can ventilate using one or more box fans, either to blow air in from the cooler side of the building or exhaust hotter air by blowing it out on the hotter side. Even better: Use fans in both locations to create a “push-pull” effect that exhausts hot air and draws in cool air. If your shop has a ceiling with an attic space above it, make sure that hot air is allowed to freely escape from the attic, either through gable or roof ridge vents. You can also mount a ventilator turbine atop the roof and use the outside breeze to exhaust hot air from either an attic or a shop with an open ceiling.

If the air outside your shop is as hot as or hotter than the air inside, there’s no sense in drawing the outside air in. In lieu of running an air conditioner, there’s one good old-fashioned option: Use a fan (or fans) to circulate the air around the shop. A portable fan or a ceiling fan will bring slightly cooler air up from the floor of the shop and circulate it around, generating a comforting breeze. By positioning the fan(s) to blow air past you, you’ll take advantage of the cooling effect that evaporating perspiration causes.

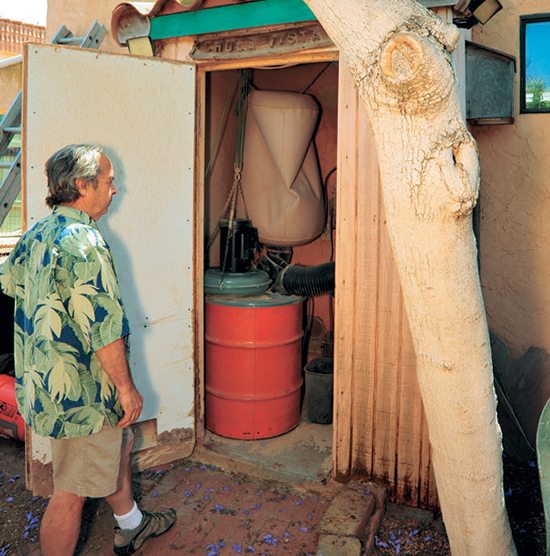

If you do plan on using ventilation to cool your shop, consider reducing the amount of heat generated inside the shop as well. Replace hot incandescent and quartz lights with cooler fluorescents and move dust collectors and compressors to a closet or attached shed. Doing so not only removes heat-producing devices from the shop, but also reduces shop noise and frees up valuable floor space as well. (If you move the dust collector, make sure the system returns filtered air back to the shop, instead of blowing it outdoors, lest your cooled — or heated — air is lost.)

Cooling the Shop

If you live and work in a place where summer temperatures regularly climb into the 90s or 100s — and sometimes stay there for days on end — your shop probably needs some form of air conditioning. There are several different types of air cooling and/or conditioning devices to choose from, including standard air conditioners, mini split systems, evaporative coolers and dehumidifiers. The best choice for your shop depends on your budget (for purchasing, installing and operating the unit), how much cooling you need and the kind of climate you live in.

Standard air conditioners employ a compressor, condenser and evaporator (same as your refrigerator) to cool the fan-blown air passing though them. Not only is the temperature of the air reduced, but its moisture content is lowered as well. While larger, industrial air conditioners have the capacity to cool large shop spaces, they’re very expensive to install and run. For smaller shops (up to 1,500 sq. ft.) located in moderate climates, a window-mounted unit is affordable, easy to install, and can lower temperatures enough to make the air more comfortable during the hottest days of summer. Air conditioners are sized by their BTU capacity, and window-mounted models typically range from 8,000 to 25,000 BTUs. A 12,000 BTU unit is about right for a two-car garage-sized shop.

One issue with running a regular household air conditioner in a woodshop is clogging due to wood dust. One way to deal with this is to simply duct tape an inexpensive fiberglass furnace filter to the front of the unit, to act as a pre-filter. Cleaning the pre-filter, as well as the air conditioner’s built-in filter, often (every day if you’re doing lots of sanding) by blowing it clean with compressed air should keep the air conditioner in good working order.

Mini splits are electric heat pump systems that not only cool your shop in the summer, but can heat it in the winter as well. The system consists of a 220-volt-powered outdoor-mounted compressor/ condenser unit that’s connect- ed via copper tubing to one or more indoor evaporator units — no expensive ductwork is needed. The outdoor unit pumps cooled refrigerant through the tubing to the indoor unit(s), and a fan blows the cooled (or heated) air around the shop. Although more expensive and trickier to install than a regular air conditioner (you do save the cost of having to install a separate heating system), a mini split system is very safe for use in a woodshop and is relatively inexpensive to run thanks to inverter technology that allows the unit’s compressor to operate at variable speeds that deliver only as much cooling/heating as needed.

Evaporative coolers are an economical alternative to standard air conditioners. They use a powerful fan to draw warm air past water-moistened pads where it is cooled by — you guessed it — the process of evaporation. The air blowing out is not only cooler, in terms of temperature, but creates a breeze which makes the ambient temperature of a shop feel several degrees lower than it actually is. Evaporative coolers come in both portable and stationary (window- or roof-mounted) models, and are sized by their CFM (cubic feet per minute) of airflow. A good rule of thumb for sizing a unit is to take the cubic (not square) footage of your shop and divide it by two. For example, a 2,400 square foot shop would need a unit rated for 1,200 CFM.

Commonly called “swamp coolers,” evaporative coolers work best in hot, dry climates where low humidity is the norm, as in the Southwest. For example, at 10% humidity, an evaporative cooler can drop shop temperatures by as much as 20 to 30 degrees; while at 50% humidity, the cooler can only lower air temperature by about 10 degrees. Clearly, an evaporative cooler is a very poor choice in regions with high summer humidity. Swamp coolers also add moisture to the air, so it’s a good idea to monitor your shop’s relative humidity with a hygrometer and make sure it doesn’t climb much above 45%.

Dehumidifiers

Speaking of high humidity, having too much moisture in the air inside your shop is definitely a bad thing: rusty tools, finishing problems, lumber with a too-high moisture content, etc. Reducing airborne moisture not only helps alleviate these problems, it can make you feel cooler, too.

A person’s perspiration helps return their skin temperature to a more comfortable level when it’s hot, and dry air favors evaporative cooling, while damp air does not. A portable electric dehumidifier provides an economical way of removing moisture from the air, and hence can make your shop feel cooler — even if the ambient temperature stays the same. This is most effective in regions that experience high humidity during hot weather.

Dehumidifiers are sized by the number of pints of water they remove from the air in a 24 hour period. You can find an online chart here that shows you the right size unit for your shop, depending on its square footage and how damp it gets. For example, a two-car garage-sized shop that’s “moderately damp” (musty odors detectable during humid weather) requires a dehumidifier rated at 10 pints.

Incorporating one or more of the insulating, cooling or dehumidifying strategies we’ve explored in this article will surely help keep your shop cooler and more comfort- able even during the hottest “dog days” of summer.