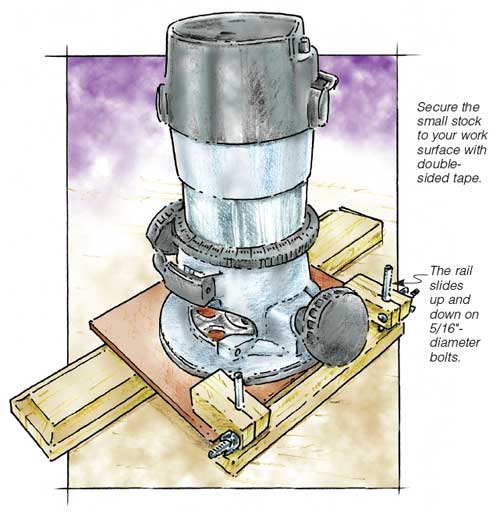

When I need to rout small narrow stock, I use the subbase shown here for added stability. The base is a piece of hardboard with two wooden clamp- blocks fastened to one edge. I made a hardwood rail with a pair of 5/16″-diameter bolts epoxied into holes in the rail. These bolts slide up and down in the jig’s wooden clamps to compensate for different workpiece thicknesses. A bolt passes through each clamp, and a wingnut locks it in place.

Once you’ve fastened the jig to the router, it’s easy to use. Set the edge of the jig on your workpiece and move the rail down to rest on the bench surface. Check to make sure the jig base is flat on the workpiece, and tighten the wingnuts. With the jig set and locked, the rail prevents the router from tipping, just like the outrigger on a boat. I attach small workpieces to the bench temporarily with double-sided tape to hold them while I rout the edges. Using this outrigger jig, routing small workpieces is smooth sailing.

– Frank Penicka

Mount Pearl, Newfoundland