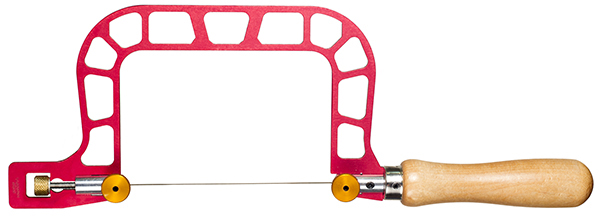

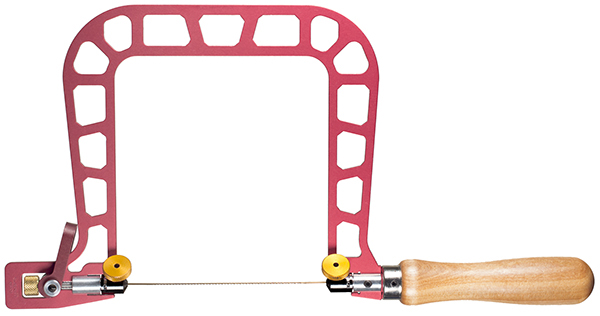

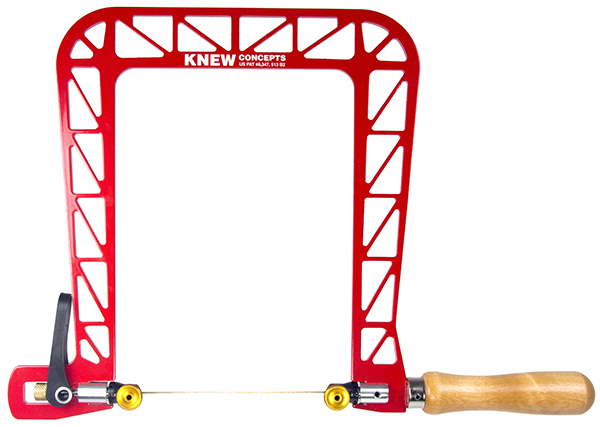

If you’ve tried fretwork, hand-cutting dovetails or coping trim moldings, you faced the decision to buy a fret saw or a coping saw somewhere along the way. And if these activities have happened within the past decade or so, you probably considered buying one of the standard metal-framed tools — you know, those coping saws you can find inexpensively at most any hardware store — or the red-framed, aluminum fret and coping saws made by Knew Concepts. They have a distinctive truss-style frame that looks more like a bridge than a beam, making the saws both lighter and much stronger than other low-dollar options.

These “red” saws were developed by Lee Marshall, a lifelong machinist and tinkerer — but originally, they weren’t made for woodworking. Instead, they were a component of Marshall’s precision die saw, which he supplied to jewelers for making controlled, vertical cuts in metal. It was a side business Marshall puttered with while building small-scale hydraulic presses — also for jewelry makers.

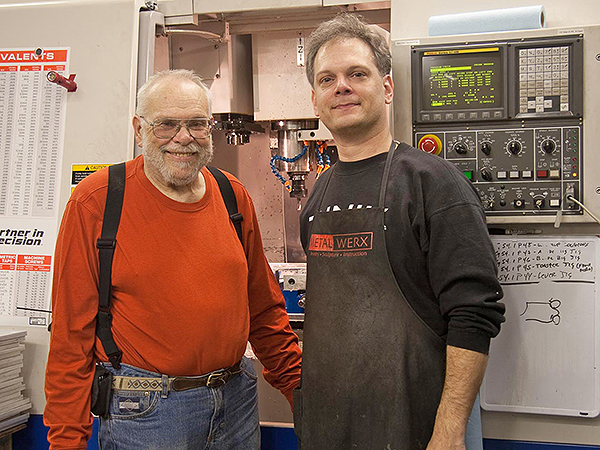

“That’s how I got to know Lee originally,” says Brian Meek, who has owned Knew Concepts since last July. “(Marshall’s) company before Knew Concepts — Bonny Doon Engineering — made those hydraulic presses for the small-scale jewelry production market. They were absolutely indispensable for production jewelry.”

Meek, who holds degrees in jewelry and metalsmithing, had his sights set on being a college art professor. To help pay the bills while looking for a teaching job, he made production jewelry and helped other jewelers make theirs.

“Just as the ‘serious’ woodworking world is pretty small, and most people know each other, the ‘serious’ jewelry world is even smaller … it was basically inevitable that (Lee and I) should end up knowing each other,” Meek says. “I knew that Lee had sold Bonny Doon and was puttering around with these saws that he’d come up with, so I offered to help him with the machining for a couple of weeks while I did some job hunting. Eight years later, I’m still here.”

When the two began to work together, Marshall was making his first “Mk.1” saw entirely by hand on manual gear. Meek brought his experience with CNC machines, graphics and production design and photography to fortify Marshall’s efforts. The combination of skills helped the business grow quickly.

“We filled in one another’s blank spots,” Meek recalls, “And before either one of us knew, it was several years down the road and I was designing most of our production line.”

At first, Marshall’s goal for the Mk.I was to service jewelry makers. But, the crossover from producing a precision metal-cutting saw to one ideally suited for wood required no extra effort for Knew Concepts.

“Fret saws and jeweler’s saws are exactly the same piece of metal; it just depends on the coarseness of the blade you load them with and what you’re cutting,” Meek says.

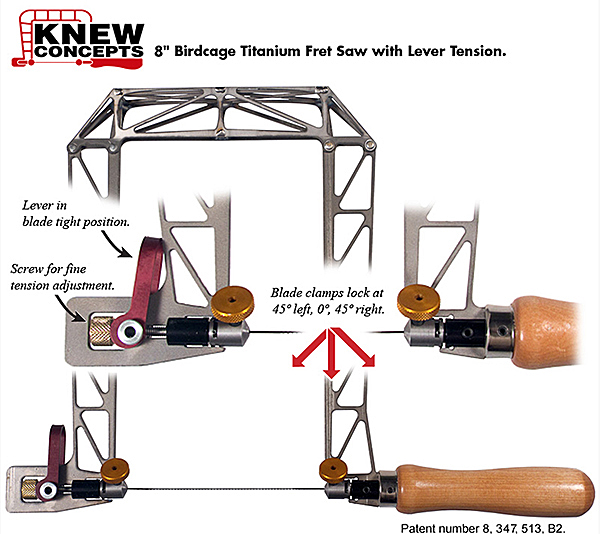

The Mk.II Fret Saw came next, and it was the first model with a truss frame made on CNC machinery rather than by hand. The Mk.III followed in around 2010, in three frame sizes. What took that version a big step forward was that Marshall and Meek figured out a way to add quick-release lever tensioning to replace the original screw tensioner. That saw required redesigning the frame in order to accommodate the levers. The company still offers Mk.III saws today as a “light” line, with slight refinements.

“The current Mk.III saws are actually Mk.IIIk, if that gives any indication of the number of minor tweaks they’ve gone through,” Meek says.

Around 2012, Knew Concepts added its first coping saw to the offerings, when the company invested in a CNC lathe that was capable of making the claws to hold the pin-style blades for them. “Once we were making (fret saws), and discovered that there was a real hunger among woodworkers for decent saws, the obvious next step was to make a coping saw that actually worked,” Meek recalls.

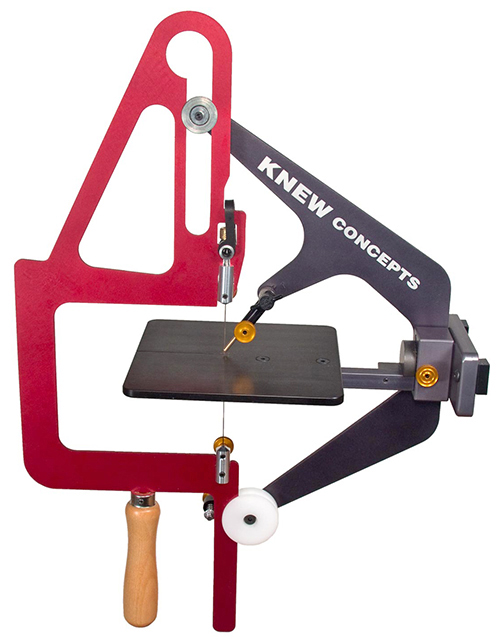

Around that same time, Marshall and Meek were “fiddling” with designs for a much larger-framed marquetry saw. That saw didn’t reach a production stage, but the efforts toward its development led to a design for blade clamps that will rotate 360 degrees. That feature, plus a modified and stronger aluminum frame design, led to the Mk.IV saws about four years later.

“We hired a structural engineer to run computer analysis on our frame designs to help us get dialed in on the strongest, lightest frame design we could … all three sizes (of the new heavy-duty Mk.IV) pull roughly the same amount of tension on their blades: 60 lbs., more or less,” Meek says. “So you don’t have the problem that traditional saws do of our frames getting looser and floppier the deeper they get. The 8-in. Mk.IV frame pulls just as hard as the 3-in. frame.”

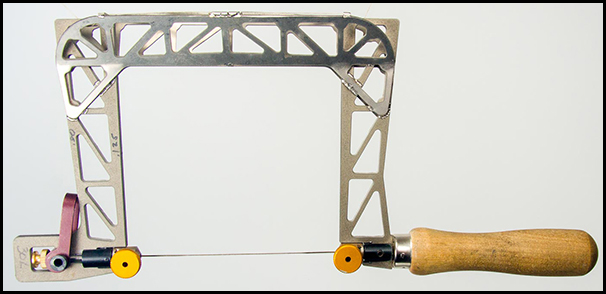

Another development happened in 2012, too: Knew Concepts began to make titanium, truss-framed fret saws. The company used surplus sheeting that had been rejected by the U.S. Air Force, due to a bad heat-treating job. The metal didn’t meet spec for an F-22 fighter plane, Meek says, but it was plenty strong enough for a hand saw frame. When the company’s supply of inexpensive sheet titanium ran out, however, customer demand for the lightweight, super-strong metal didn’t. On top of that, comparable titanium was four times more expensive than the scrap material Knew Concepts had used previously, and the “flat” truss frames were difficult to nest efficiently without wasting excess material.

The solution to the problem came fortuitously and in a fit of frustration after about six months of trial and error. Puzzle-piecing a flat, titanium truss frame together, in order to economize material, just didn’t work. “Some (frames) were strong as anything but had no torsional (twisting) strength at all,” Meek recalls. The breakthrough happened when he bent a spine into a “V” shape and welded cross-members over the valley, zigzag fashion.

“Bingo! That truss didn’t bend at all, and that’s where our Birdcage Titanium Fret Saws came from,” Meek says. The company now sells them in three frame sizes, along with its Mk. III and Mk. IV aluminum saws.

Last June, after a brief battle with cancer, Lee Marshall passed away. Meek bought the business shortly thereafter. He says his plans going forward are to continue the full line of Knew Concepts saws. He also hopes to launch that earlier marquetry saw this summer at some point.

“It’s the last thing Lee and I worked on together,” Meek says. “We’re cutting parts for it now; it’s just a matter of getting machine time to get all the parts made. It will be available in three lengths of leg — 12, 18 and 24 in. — and all three sizes can pull at least 60 pounds of tension.”

When asked about the company’s most popular woodworking saw, Meek clarifies that neither a fret nor a coping saw can do every task with equal finesse — fret saws are best for intricate work and making tight turns, while coping saws handle coarse work and straight cuts better. That said, he offers the following suggestion.

“If you can have only one, get the fret saw: it can drop into the vertical of a dovetail, turn 90 degrees at the bottom and zoom straight across the waste. Coping saws need to sweep in from both sides and still leave that peak in the middle to deal with.”

Which model is most popular, you might wonder? Meek says it’s the Mk. III or Mk. IV 5-in. Fret with blade swivels. “By a long shot,” he adds.

“The 5-in. size isn’t vastly heavier than the 3-in. model, and it gives more flexibility in terms of the work it can do. If you know you’ll only ever be clearing out dovetail waste, get the 3 in. If you don’t know what you’re going to end up doing, get the 5-in.”

Aside from the forthcoming marquetry saw, Meek reveals that other new products are in the works, plus extensions and refinements to existing products. But with Marshall now gone, Meek spends more time in the office, and he misses the opportunity to get out on the road and attend more shows. That’s where he’s enjoyed meeting customers, seeing the sorts of work they do and discovering ways Knew Concepts might be able to help them do it even better.

“That’s the fundamental thing for both Lee and I: the pleasure of being able to use our unique skill sets to make our friends’ lives easier and their work better,” Meek says. “My plan for Knew Concepts is to keep figuring out ways to help as many craftspeople as I can.”

Learn more about Knew Concepts and its product line by clicking here.